The Automatic Vial Monoblock Filling Capping Machine is an integrated solution designed for high-precision filling and secure capping of vials in the pharmaceutical, cosmetic, and biotechnology industries. Made from SUS316L/SUS304 stainless steel, it fully complies with GMP standards, ensuring product hygiene, durability, and cleanroom compatibility.

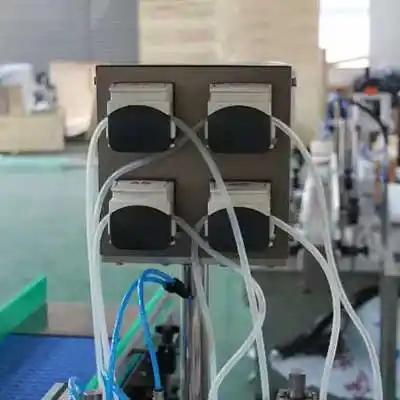

This system combines automatic vial feeding, filling, stoppering, and capping into one compact unit. Using peristaltic pump, it achieves a filling accuracy of ±0.5–1%, suitable for liquids, syrups, and small-dose sterile products. Advanced features like no bottle no filling, no cap no capping, and anti-drip filling nozzles ensure reliable, contamination-free production.

Controlled by a PLC system with a touch screen interface, operators can easily adjust parameters and monitor performance in real time. Its modular design allows seamless integration with labeling or packaging lines, making it ideal for high-speed, automated production environments.

Monoblock Filling Capping Machine Feautures

1.Integrated Filling & Capping System

Combines vial filling, stoppering, and capping in one compact structure, ensuring continuous and efficient production with minimal space requirement.

2.Advanced Filling Technology

Utilizes precision piston or peristaltic pump systems for accurate dosing, bubble-free filling, and consistent volume across all vials.

3.Automatic Detection & Safety Control

The system automatically detects missing or misaligned vials and stops operation to avoid spillage and waste, ensuring reliable performance.

4.Precision Cap Placement

The capping head applies uniform torque, preventing cap deformation and maintaining product aesthetics.

5.Easy Operation & Adjustment

User-friendly PLC touchscreen interface allows quick setup, parameter modification, and real-time monitoring of the production process.

6.Hygienic & Durable Design

Made from high-quality 304/316L stainless steel, the machine meets GMP standards for sterile pharmaceutical environments.

7.Flexible Application

Suitable for different vial sizes and liquid viscosities, widely used in pharmaceutical, cosmetic, and biotech liquid packaging lines.

Technical Parameters

| 1 | Yield capacity | 80-100pcs/min |

| 2 | Filling station | 4 |

| 3 | Filling accuracy | ±1% |

| 4 | Filling range | 5ml to 200ml |

| 5 | filling tolerance | ±1% |

| 6 | Capping station | tow |

| 7 | Qualified cap putting | more or equal then 99% |

| 8 | Qualified capping | more or equal then 99% |

| 9 | Speed regulation | by inverter |

| 10 | power supply | 380V 50Hz |

| 11 | Power | 3.5kw |

| 12 | outside dimension | 1410×1170×1850mm |

How the Fill-Plug-Cap-Torque System Works?

At the heart of the Monoblock Filler is a carefully synchronized Fill-Plug-Cap-Torque system that manages every stage with efficiency and accuracy. Here’s how it works:

Filling: Precision is key, so the system uses advanced dispensing methods like volumetric pistons or peristaltic pumps. This ensures that whether you’re working with watery serums or viscous creams, each container receives the exact amount of product required.

Plugging: Once filled, containers move to the plugging station. Here, the system automatically inserts stoppers, plugs, or dropper inserts—an essential step for products that require an intermediate closure before capping.

Capping: Next up is the application of caps or closures. A torque-controlled mechanism applies consistent force, securing each cap to the optimal tightness. This not only prevents leaks but also maintains product integrity during shipment and storage.

Movement and Precision: Guiding containers through every stage is a servo-controlled starwheel or similar indexing mechanism. This approach offers reliable positioning, even as container sizes or fill volumes vary between batches.

In short, the Fill-Plug-Cap-Torque system effortlessly combines speed and accuracy, optimizing your packaging line for diverse liquid products across multiple industries.

Accessories for Monoblock Filler Capper Machines

Monoblock filling capping machines support a range of auxiliary equipment to enhance automation, hygiene, and compliance.

Feeding Systems

Bottle, vial, and cap feeders ensure smooth and continuous material supply.

Sterilization Equipment

Tunnel sterilizers or depyrogenation units keep containers contaminant-free before filling.

Labeling and Coding

Labelers and coders apply batch and expiry information for traceability.

These accessories enable a compact, efficient, and compliant monoblock liquid filling and stoppering line.