The Deodorant Filling Machine is specially designed for accurate and efficient filling of stick-type deodorant containers. It supports liquid, gel, and solid deodorant formulations, delivering precise filling performance and uniform results across all bottles through a fully automated process.

Widely used in the personal care industry, this automatic deodorant filling solution is ideal for high-efficiency production of deodorant sticks. Its flexible design also allows it to accommodate similar stick products, making it a scalable option for expanding manufacturing requirements.

The machine integrates multiple functions into one streamlined system, including filling, stick insertion, and capping. Capable of handling different container sizes, fill volumes, and packaging designs, the Deodorant Stick Filling Machine ensures stable operation, high productivity, and consistent product quality.

Key Features of Deodorant Filling Machines

Precise Filling Control

Equipped with advanced sensors and volumetric filling systems, the machine ensures accurate dosing, consistent quality, and minimal product waste.

High-Speed Efficient Operation

Automated filling and capping processes enable stable output of approximately 20–40 units per minute, meeting high-volume production demands.

Flexible Customization

Supports adjustable filling volumes (10–100 ml) and various container shapes, making it suitable for different deodorant stick products and production requirements.

Technical Parameters

| 1 | Filling speed | 35-40 bottles/min |

| 2 | Filling precision | ≥99% |

| 3 | Finished product rate of cap drop | ≥99% |

| 4 | Main machine power | 1KW 220V stepless shift |

Working Process of Automatic Deodorant Filling Machine for Stick Bottles

Bottle Loading & Positioning

Empty stick bottles are automatically fed into the machine via a conveyor or rotary table and precisely aligned using sensors to ensure accurate positioning under the filling nozzles.

Filling Process

The filling nozzles dispense a preset volume of deodorant into each bottle, controlled by a piston or peristaltic pump. Anti-drip design ensures clean, accurate, and consistent filling.

Bottle Transfer

Filled bottles are smoothly conveyed to the capping station without interruption.

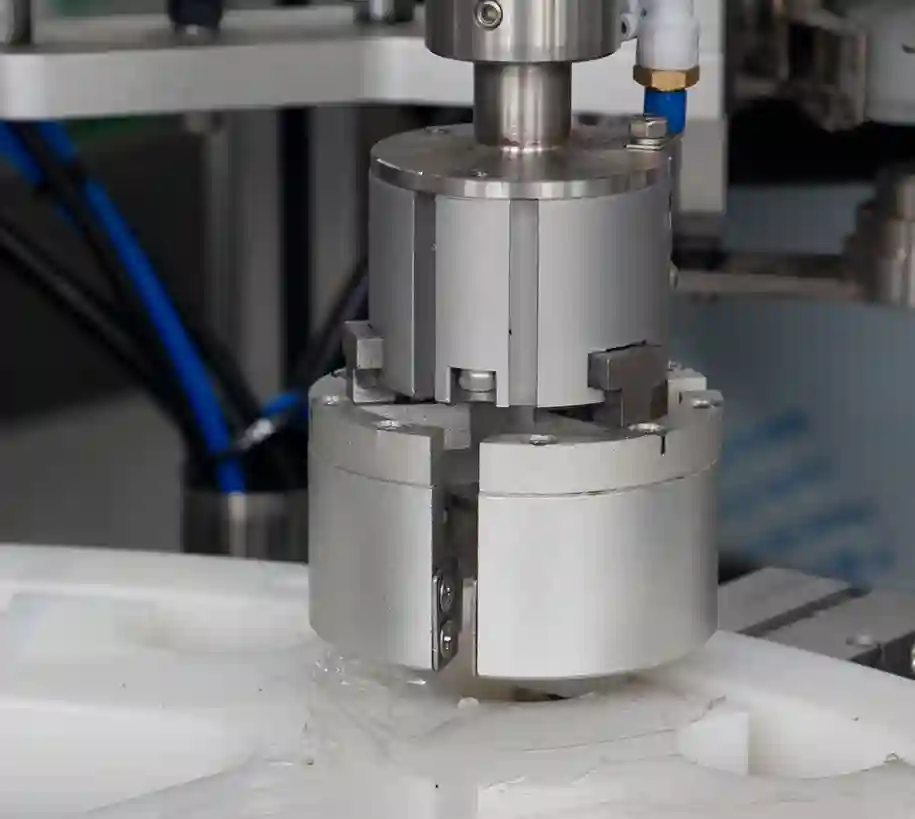

Cap Feeding & Capping

Caps are automatically sorted and positioned, then securely applied with controlled torque using capping systems.

Finished Product Discharge

Completed bottles are discharged onto the output conveyor for labeling, packaging, or further processing.

By integrating filling, capping, and conveying into a continuous workflow, the deodorant stick filling machine delivers stable performance, high efficiency, and hygienic production.

Maintenance and Troubleshooting for Deodorant Filling Machines

Routine Maintenance

Daily Cleaning: Clean all product-contact parts, filling nozzles, and conveyors after each shift to prevent residue buildup and contamination.

Regular Lubrication: Lubricate moving components such as guide rails and bearings according to the manufacturer’s maintenance schedule.

Component Inspection: Periodically check pumps, seals, and cap feeding systems for wear, and replace damaged parts promptly.

Calibration Checks: Verify filling accuracy and capping torque regularly to ensure consistent product quality.

Common Troubleshooting Tips

Inconsistent Filling: Often caused by air in the system or blocked nozzles; bleed air, clean nozzles, and recalibrate pumps.

Cap Misalignment: Check cap feeders for blockages, improper orientation, or worn parts, and adjust as needed.

Machine Jams: Remove foreign objects, clear excess material, and inspect sensors for proper function.

Post-Filling Leakage: Adjust fill volume, ensure correct container positioning, and replace faulty seals.

Following these practices helps maintain stable performance, reduce downtime, and ensure reliable deodorant production.

What Factors Should Be Considered When Choosing a Deodorant Filling Machine?

An automatic deodorant filling machine is specifically designed for producing deodorant and antiperspirant sticks. It can process materials with different viscosities, including solid pastes, creams, gels, and formulations containing exfoliating or frosted particles.

When selecting a suitable machine, manufacturers should evaluate their actual production requirements. Key considerations include output capacity, container shapes and sizes, and available factory space. Equipment with adjustable filling volumes, compatibility with multiple container types, and flexible or modular configurations offers greater adaptability for future product variations.

By carefully assessing these factors, you can select a deodorant filling machine that ensures stable performance, consistent product quality, and long-term production flexibility.