Automatic Fragrance Filling Machine is designed for precise filling of perfume and fragrance liquids into small glass or rigid plastic bottles, with a capacity range of 10–250 ml, suitable for a wide variety of container types. Controlled via an advanced PLC system, it features high-quality pneumatic and electrical components from renowned international brands, ensuring reliable performance and long-term durability. The machine frame is constructed from 304 stainless steel, fully compliant with GMP standards and CE certified, guaranteeing safety and hygiene.

Built for high-efficiency production, the machine delivers accurate dosing while maintaining the integrity of delicate fragrances. It supports multi-nozzle filling, with the number of filling heads adjustable to meet different production requirements.

Automatic Fragrance Filling Machine Features

Touch Screen & PLC Control System

Equipped with a color touch screen and advanced PLC control, the machine offers intuitive operation, easy parameter adjustment, and reliable process control.

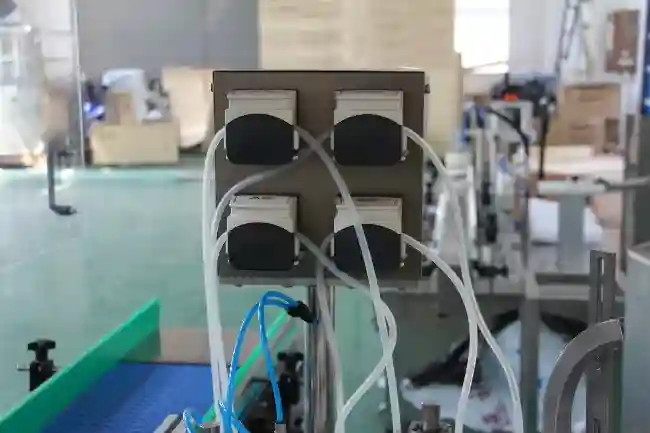

Stainless Steel Peristaltic Pump for Precise Filling

A high-precision stainless steel peristaltic pump enables accurate quantitative filling, ensuring consistent volume control for each bottle.

Accurate Filling with Stable Capping

The system delivers precise filling performance combined with smooth and stable capping, improving overall production efficiency and product consistency.

High Automation & Clean Operation

Fully automated operation minimizes manual intervention, ensuring a clean, pollution-free filling process suitable for fragrance and cosmetic applications.

304/316 Stainless Steel Structure

Product-contact parts are 316 stainless steel, and the frame is 304 stainless steel, meeting strict hygiene standards.

Cap Placement Device

A dedicated cap placement mechanism ensures accurate positioning of spray caps or long nozzle pipes at the bottle mouth, reducing misalignment and rejects.

Technical Parameters

| 1 | Filling speed | 35-40 bottles/min |

| 2 | Filling precision | ≥99% |

| 3 | Finished product rate of cap drop | ≥99% |

| 4 | Main machine power | 1KW 220V stepless shift |

Applications of the Automatic Fragrance Filling Machine

The automatic fragrance filling machine efficiently fills liquid perfumes into various bottle types, including glass and rigid plastic, without the need for weight adjustments. It is widely used in cosmetics, pharmaceuticals, chemicals, and related industries.

Suitable for a variety of products, including:

Perfume

Fragrance oils

Gel-based liquids

Sprays

Aerosols

Cbd Oil

E-liquid

With its versatile capabilities, this machine provides precise, high-efficiency filling for businesses across multiple sectors.

Complete Perfume Filling System and Required Equipment

A full perfume production and filling system involves a range of specialized machines to ensure efficiency, consistency, and product quality. Key equipment includes:

Production Machines:

Extraction Machines – Obtain aromatic compounds from raw materials.

Alcohol Distillation Machines – Purify alcohol for fragrance solutions.

Mixing Tanks & Homogenizers – Blend ingredients evenly for batch consistency.

Filtering Machines – Remove impurities, ensuring clarity and purity.

Quality Control & Climate-Controlled Equipment – Maintain standards and optimal storage conditions.

Packaging Machines:

Liquid Filling Machines – Accurately dispense perfume into bottles of various shapes and sizes.

Capping & Sealing Machines – Secure atomizers, spray tops, or caps for airtight, professional sealing.

Labeling & Cartoning Machines – Apply labels and pack bottles for branding, compliance, and shipping.

When integrated, these machines form a seamless perfume production line, enabling efficient, hygienic, and consistent manufacturing from raw material to finished product.

Challenges in Fragrance Packaging and Solutions

Packaging fragrance involves unique challenges, especially regarding safety, scent integrity, and efficiency. Key considerations include:

1. Handling Flammable Liquids

Perfumes often contain high alcohol content, making them highly flammable. Using explosion-proof filling machines eliminates sparks and ignition sources, ensuring safe handling. Reliable components from brands like Siemens and Omron are commonly used in such equipment.

2. Preventing Cross-Contamination of Scents

Maintaining fragrance purity is essential. Peristaltic pump filling machines allow quick tubing changes between batches, reducing residual scents and ensuring each batch delivers its intended aroma.

3. Accommodating Various Spray Caps

Perfume bottles come with different spray caps and neck sizes. Modern capping machines feature adjustable chucks and flexible heads to handle diverse cap types efficiently, enhancing versatility and production speed.

4. Filling Unstable or Unique Bottle Shapes

Irregular bottles may not stand upright during filling. Custom bottle fixtures and molds securely hold these containers, preventing spills and ensuring precise, consistent production.