The Automatic Jar Monoblock Filling Capping Machine combines liquid filling and capping into a compact, fully automated system designed for efficiency, precision, and hygiene. It is ideal for food, cosmetics, pharmaceuticals, and chemical products such as creams, sauces, lotions, and essential oils.

Equipped with a PLC control system and touch screen interface, the machine ensures easy operation, real-time monitoring, and precise parameter adjustment. It supports piston filling, achieving a high filling accuracy of ≤±0.5%, while the anti-drip filling nozzles prevent leakage and ensure a clean working environment.

The integrated servo-driven capping system delivers consistent torque control, automatically detecting and rejecting missing or misaligned caps. Built from SUS304/316 stainless steel to meet GMP and CE standards, this monoblock machine offers stable performance, quick changeover between bottle sizes, and long service life—making it the perfect choice for modern automated packaging lines.

Automatic Jar Monoblock Filling Capping Machine Features

1.Smart PLC Control System

Equipped with an advanced PLC and touchscreen interface, this machine allows easy adjustment of filling volume, capping torque, and production speed. It saves time, reduces energy consumption, and ensures precise operation with minimal downtime.

2.Accurate Bottle Detection & Positioning

A photoelectric sensor automatically detects incoming jars, ensuring correct bottle orientation before filling. It prevents overflow, missing caps, and misaligned bottles, enhancing reliability throughout the filling and capping process.

3.High-Precision Filling Technology

Each filling nozzle is individually controlled and driven by a servo motor for exceptional accuracy (≤0.5%). Designed for different liquid viscosities, the nozzles feature an anti-drip structure to ensure clean, efficient filling.

4.Automatic Capping & Torque Control

The integrated capping system automatically picks, places, and tightens caps with consistent torque. It’s suitable for plastic or glass jars and ensures stable sealing performance across various cap types.

5.Hygienic & Durable Construction

All parts in contact with the product are made of SUS316 stainless steel, meeting GMP and food-grade standards. The machine structure is compact, corrosion-resistant, and easy to clean and maintain.

6.High Efficiency & Safety System

Production speed ranges from 1800 to 2400 jars per hour. Safety features include automatic stop and alarm for missing bottles, caps, or plugs, ensuring operator safety and continuous, stable operation.

Technical parameters

| 1 | Filling speed | 35-40 bottles/min |

| 2 | Filling precision | ≥99% |

| 3 | Finished product rate of cap drop | ≥99% |

| 4 | Main machine power | 1KW 220V stepless shift |

Working Process of the Jar Monoblock Filling Capping Machine

Bottle Infeed

Empty plastic/glass bottles are fed into the machine by conveyor belt. A bottle separation mechanism automatically adjusts the spacing between containers to ensure orderly and continuous transfer.

Bottle Positioning

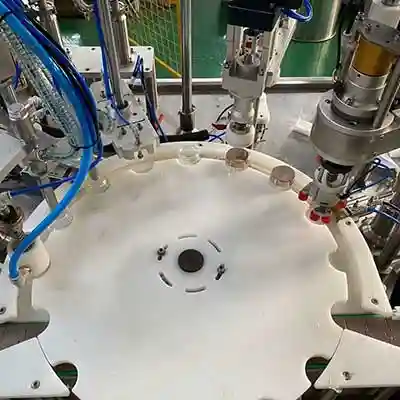

The bottles are guided into the star wheel pockets, which accurately index and transport each container to the exact position beneath the filling nozzles.

Filling Operation

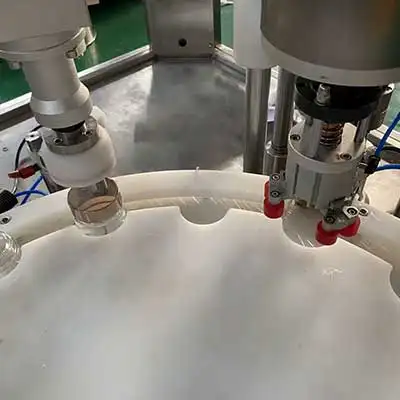

Once correctly positioned, the filling nozzles descend and insert into the bottle mouths. The piston-driven filling system dispenses the liquid with high precision, ensuring consistent and accurate fill volumes.

Cap Feeding and Capping

After filling, bottles are rotated by the star wheel to the capping station. The cap pick-up mechanism places a cap onto each bottle. The capping head then lowers, grips the cap, and rotates it until the preset torque value is reached, guaranteeing secure and uniform sealing.

Bottle Discharge

Finished bottles are released from the star wheel onto the discharge conveyor and transferred to downstream equipment, such as labeling machines or carton packing systems.

How to Troubleshoot Common Issues with a Jar Monoblock Filling Capping Machine?

- Check for Blockages

Clean product lines, nozzles, and valves to prevent filling inconsistencies. - Verify Settings

Confirm filling volume settings and calibration for the current product. - Inspect Air and Power Supply

Ensure stable air pressure and secure pneumatic and electrical connections. - Check Sensors

Inspect sensors and safety devices for contamination or misalignment. - Confirm Change Parts

Verify correct installation of guides, star wheels, and changeover parts.

If problems continue, consult the operation manual or contact technical support.

What Maintenance and Inspection Practices Are Recommended for a Jar Monoblock Filling Capping Machine?

Maintenance & Inspection Key Points

- Follow the manufacturer’s operation and maintenance guidelines

- Wear proper safety equipment during inspection and servicing

- Clean all product-contact parts after each production run

- Regularly inspect seals, valves, and conveyors for wear or leakage

- Check alignment and lubrication of filling nozzles and capping heads

- Replace consumable parts in advance as part of preventive maintenance

- Troubleshoot abnormal operation promptly to avoid downtime