In the personal care market, the quality and efficiency behind every tube of toothpaste rely on advanced, stable, and precise toothpaste filling machine,it is not simply used to dispense product; it plays a strategic role in boosting production capacity, maintaining uniform quality, and enhancing a brand’s competitiveness. Selecting the right toothpaste filling solution has a direct impact on manufacturing efficiency, cost management, and sustainable business growth.

As a professional and established manufacturer of personal care filling equipment, Shanghai Npack has over 15 years of experience in the research, design, manufacturing, and commercialization of filling and packaging machines. We have provided customized filling solutions for globally recognized brands such as Unilever, PT SINAR, and DMCG. Our long-term involvement with a wide range of toothpaste formulations and packaging formats has enabled us to gain in-depth knowledge of the technical complexities and strict quality requirements of toothpaste filling operations.

In this ultimate guide to the toothpaste filling machine, we will share our hands-on experience and industry insights from several key angles, providing readers with a clear, practical, and comprehensive understanding of toothpaste filling technologies and best practices.

What is toothpaste?

Toothpaste is a paste or gel dentifrice that is used with a toothbrush to clean and maintain the aesthetics of teeth. Toothpaste is used to promote oral hygiene: it is an abrasive that aids in removing dental plaque and food from the teeth, assists in suppressing halitosis, and delivers active ingredients (most commonly fluoride) to help prevent tooth decay (dental caries) and gum disease (gingivitis). Common colors for toothpaste include white (sometimes with colored stripes or green tint) and blue. from Wiki

What is toothpaste packaged in?

Toothpaste is most commonly packaged in tubes, also known as squeeze tubes or collapsible tubes, which are designed for convenience, hygiene, and controlled dispensing. While the tube format is standard across the industry, the materials used can vary, each offering distinct advantages and limitations.

Plastic Laminate Tubes (PBL)

- Lightweight, flexible, and cost-effective.

- Widely used for mass-market toothpaste products.

- Recycling can be challenging in some regions due to multilayer plastic construction.

Aluminum Tubes

- Offer excellent protection against air, light, and moisture.

- Often used for sensitive, natural, or specialty toothpaste formulas.

- Fully recyclable, but prone to denting during handling.

Aluminum Barrier Laminate Tubes (ABL)

- Combine plastic and aluminum layers for both flexibility and strong barrier performance.

- Suitable for toothpaste requiring extra protection.

- Mixed materials make recycling more complex.

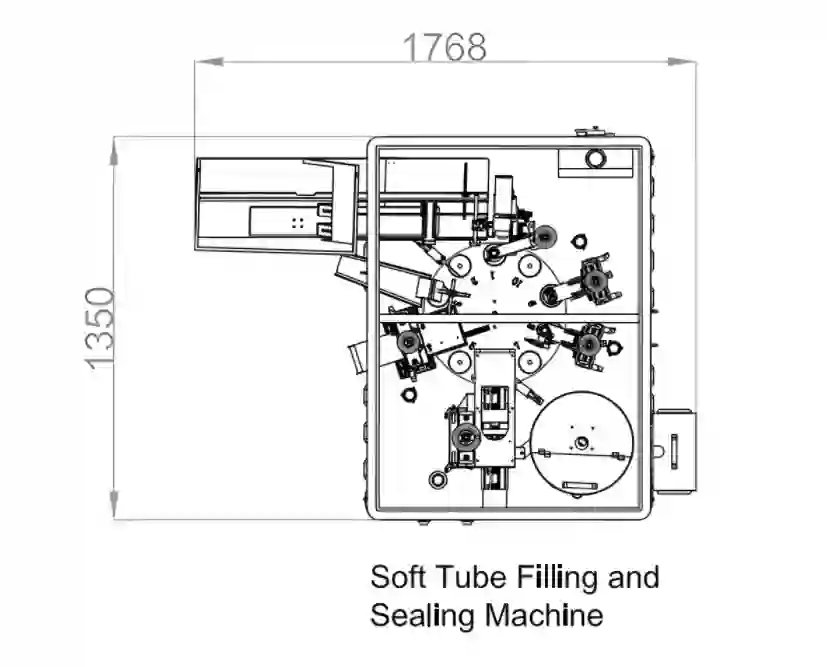

There are a full range of tube filler and sealer machine in macket, including semi-automatic models, fully automatic systems, and high-speed tube filling and sealing machines to support efficient and scalable toothpaste packaging operations

What Is a Toothpaste Filling Machine?

A toothpaste filling machine is a purpose-built system designed to accurately fill high-viscosity products—such as toothpaste, ointments, and cosmetic creams—into tubes and then automatically seal the tube ends. As a key component of modern toothpaste production lines, this equipment ensures consistent filling, hygienic operation, and reliable sealing. It is widely applied across industries including pharmaceuticals, cosmetics, food processing, and personal care manufacturing.

Main Components of a Toothpaste Tube Filling Machine

Most toothpaste tube filling and sealing machines share a standardized structure designed for stable, hygienic, and efficient production.

Safety System

Equipped with a complete safety protection system, including emergency stop buttons, fault alarms, and electrical interlocks. The design prevents access to electrical parts when power is on, ensuring operator safety and compliant operation.

Machine Frame

Heavy-duty frame construction provides strong structural support and stable operation during high-speed filling and sealing processes.

Material Tank & Hopper

The stainless steel material tank stores toothpaste and supplies it to the hopper automatically. The funnel-shaped hopper ensures smooth material flow and continuous feeding.

Filling Nozzle System

High-precision filling nozzles are connected to the hopper and designed for accurate dosing, smooth flow, and minimal material waste. Suitable for single-color and multi-color toothpaste filling.

Tube Holding & Conveyor System

Tube holders accurately position empty tubes, while the conveyor system indexes tubes through filling, sealing, and discharge stations for continuous production.

Sensor & Dosing Control

Photoelectric sensors detect tube presence and trigger filling. The dosing system ensures consistent filling volume for each tube, improving product uniformity.

Sealing (Coding) Jaws

Sealing jaws securely close the tube ends and can emboss batch numbers or production dates, ensuring reliable sealing and traceability.

Cooling Unit

A rapid cooling unit stabilizes the tube seal after sealing, improving sealing strength and extending product shelf life.

PLC Control Panel

The machine is operated via an intelligent PLC control system with a user-friendly interface. Filling volume, tube size, and color options can be easily set, and alarms are triggered if parameters exceed preset limits.

Motor Drive System

Powered by durable electric motors, the toothpaste tube filling machine delivers reliable performance with low maintenance requirements, suitable for semi-automatic and fully automatic configurations.

Types of Toothpaste Filling Machines

Based on the level of automation and production capacity requirements, toothpaste tube filling machines can be classified as follows:

1. Manual or Semi-Automatic Filling Machine

Designed for small-scale production, pilot runs, or laboratory applications. Tubes are placed manually, and the operator controls the filling and sealing process.

2. Fully Automatic Tube Filling and Sealing Machines

Capable of automatic tube loading, precise filling, tail sealing, date or batch coding, and finished tube discharge. These machines are well suited for medium- to large-volume toothpaste manufacturing.

3. Automated Filling and Packaging Lines

Integrated systems that connect tube filling machines with labeling machines, cartoners, vision inspection units, and other downstream equipment, delivering a fully automated and high-efficiency packaging solution.

Toothpaste Filling Machines Application

| Application Industry | Typical Products |

| Personal Care | Toothpaste, facial cleansers, hair conditioners, gels |

| Food | Tomato paste, salad dressings, honey, peanut butter |

| Pharmaceutical | Ointments, gels, eye creams, topical medications |

| Cosmetics | Face creams, sunscreen, whitening creams |

| Stationery | Watercolors, oil paints |

| Pet Products | Pet toothpaste, ointments, nutritional pastes |

Benefits of Using a Toothpaste Filling Machine

A toothpaste tube filling machine is an efficient and hygienic solution for toothpaste packaging. As a reliable China toothpaste filling machine manufacturer, we offer automated equipment with advanced PLC control to ensure stable and precise operation.

Compatible with Various Toothpaste Formulations

The toothpaste tube filling and sealing machine is suitable for gels, creams, and high-viscosity pastes, supporting quick changeovers and single- or multi-color toothpaste filling.

High Efficiency and Consistent Quality

Automatic operation improves production efficiency, reduces labor costs, and minimizes material waste. Precise filling and sealing ensure uniform tube appearance and leak-proof packaging.

Hygienic Design and Easy Maintenance

Made of stainless steel, with easy-to-clean product contact parts, the machine meets strict hygiene requirements and reduces contamination risks.

CE-Certified for Global Markets

The equipment can be supplied with a CE certificate, making it suitable for European and international toothpaste production lines.

For most toothpaste manufacturers, tube filling and sealing machines are the preferred packaging solution. Based on different production capacities and tube materials, Npack leverages its project experience to recommend the following toothpaste tube filling and sealing machines.

Toothpaste Filling Machine for Aluminum Tubes

Aluminum tube filling and sealing machines are the most commonly used equipment for packaging toothpaste in aluminum tubes. They are specifically designed to accommodate the characteristics of aluminum tubes, significantly increasing production efficiency while reducing manual intervention, minimizing contamination risks, and lowering labor costs.

The Automatic Aluminum Tube Filling and Sealing Machine is a high-precision solution for viscous, sticky, or paste products. It integrates tube feeding, orientation, piston filling, tail sealing, date/lot coding, and automatic discharge, ensuring consistent quality and minimal waste.

Toothpaste Filling Machine for Plastic Laminate Tubes (PBL)

Ultrasonic tube filling and sealing machines are the primary equipment used for packaging toothpaste in Plastic Laminate Tubes (PBL). They provide strong and aesthetically clean seals without damaging the layered structure, making them especially suitable for Plastic Laminate Tubes (PBL).

The Automatic Ultrasonic Tube Filling and Sealing Machine is an advanced solution designed for precise and efficient filling of creams, gels, lotions, and other viscous materials. Using ultrasonic sealing technology, it provides strong, clean, and reliable seals without preheating, ensuring superior product integrity and appearance.

Toothpaste Filling Machine for Aluminum Barrier Laminate Tubes (ABL)

Automatic inner heating tube filling and sealing machines are the primary equipment for packaging toothpaste in Aluminum Barrier Laminate Tubes (ABL). They provide high sealing strength, excellent airtightness, and a smooth, aesthetically clean seal appearance.

The Automatic Inner Heating Tube Filling Sealing Machine is designed for efficient and precise filling, sealing, and date printing of plastic and laminated tubes with creams, gels, lotions, and other viscous products. Featuring inner hot air heating technology, it ensures clean, firm, and aesthetically appealing seals.

Customer Case Study-Poland Toothpaste Tube Filling and Sealing Project (2024)

In 2024, we successfully delivered a customized toothpaste and hand cream tube filling and sealing solution for a client in Poland. This project highlights how modern ultrasonic tube filling and sealing machines can improve efficiency, precision, and packaging quality for personal care products.

Customer Requirements:

The client needed a system that could deliver high-precision filling, secure sealing, and a clean, attractive tube appearance, ensuring consistent product volume and quality across every batch.

Core Technology:

Our solution used ultrasonic tube filling and sealing technology, where high-frequency vibrations achieve low-temperature, contactless sealing. This method prevents product overheating and eliminates the risk of tube contamination, making it ideal for delicate creams and toothpaste.

Design Highlights:

High-precision piston filling system for accurate and stable dosing

Digitally adjustable ultrasonic sealing station compatible with multiple tube materials

Compact, stable structure supporting continuous, high-speed production

Project Results:

The equipment helped the client successfully improving production efficiency while maintaining consistent product quality and professional packaging.

What Frequently Asked Questions Do Customers Have About Toothpaste Filling Machines?

Frequently Asked Questions About Toothpaste Filling Machines

Selecting a toothpaste filling machine often comes with many questions, whether you are purchasing automated equipment for the first time or upgrading an existing production line. Below are answers to the most frequently asked questions from our customers to help you make an informed decision.

Can Toothpaste Filling Machines Handle Different Tube Sizes?

Yes. Modern toothpaste filling machines feature adjustable mechanisms that can handle a wide range of tube diameters and lengths—from small sample tubes to standard retail sizes (commonly 16–55 mm in diameter). This versatility makes them well-suited for brands producing multiple packaging formats or specialized SKUs.

How Accurate Is the Filling Process?

Accuracy is critical. Advanced toothpaste filling systems—commonly used in pharmaceutical and cosmetic production—are equipped with sensor-controlled dosing and high-precision piston filling technology. These systems deliver extremely consistent fill volumes, typically keeping deviations below 0.2 g (or 0.2 ml), ensuring reliable quality across every production batch.

Will the Machine Detect If a Tube Is Missing?

Yes. Automated tube detection is now a standard feature in modern toothpaste filling machines. If a tube is misaligned or not properly positioned, the system automatically stops the filling process and alerts the operator, greatly reducing the risk of spills and product waste

What Filling Capacities Are Supported?

Toothpaste filling machines are generally highly versatile in handling different volumes. Most can fill tubes ranging from around 5 ml (for travel-sized tubes) up to 300 ml or more, making them suitable for both small trial packs and larger family-sized tubes. Volume adjustments are easily managed through the machine’s control panel.

What Types of Sealing Methods Are Available?

The main sealing methods are ultrasonic sealing—best for plastic and laminated tubes because it creates clean, strong seams—and hot air inner heating, which is typically used for aluminum barrier laminate tubes. Both methods ensure hygienic, tamper-evident seals while minimizing tube deformation. Some machines also include water cooling systems to prevent overheating and protect the product.

These explanations provide a clear overview of what to expect from a toothpaste filling machine, covering aspects such as versatility, accuracy, production efficiency, and sealing technology.

Conclusion

Investing in the right toothpaste filling and sealing equipment is a strategic decision that directly impacts production efficiency, product quality, and brand reputation. Whether handling aluminum, plastic laminate, or barrier laminate tubes, modern automated solutions—like ultrasonic or inner heating machines—ensure precise filling, hygienic sealing, and consistent appearance, while reducing labor costs and minimizing waste.

With over 15 years of experience and a proven track record serving global brands, Shanghai Npack delivers tailored, high-performance toothpaste filling solutions that meet the diverse needs of personal care manufacturers. From semi-automatic machines for small-scale production to fully integrated high-speed lines, our equipment helps businesses achieve scalable growth, maintain product integrity, and stay competitive in the dynamic personal care market.

By choosing advanced toothpaste filling technology, manufacturers can confidently streamline operations, optimize resources, and deliver high-quality products that stand out in a crowded marketplace.