The Automatic Inner Heating Tube Filling Sealing Machine is designed for efficient and precise filling, sealing, and date printing of plastic and laminated tubes with creams, gels, lotions, and other viscous products. Featuring inner hot air heating technology, it ensures clean, firm, and aesthetically appealing seals.

Equipped with a PLC control system, touch screen interface, and photoelectric tube positioning, the machine allows real-time adjustment of filling volumes and delivers stable, high-speed operation with minimal noise. It integrates automatic tube feeding, orientation, filling, sealing, coding, and discharge in one streamlined system, making it ideal for cosmetics, pharmaceuticals, food, and chemical industries. Its robust design combines simplicity, reliability, and ease of maintenance, enhancing production efficiency while maintaining superior packaging quality.

Inner Heating Tube Filler and Sealer Machine Features

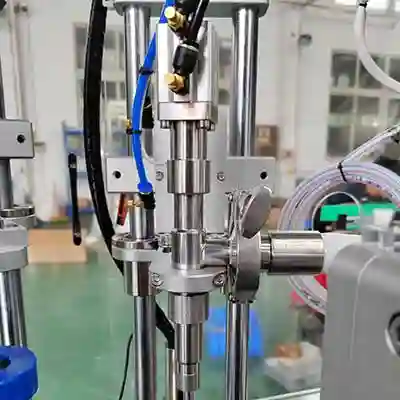

1.Advanced Inner Heating & Sealing

Double-layer jacket instant heater with internal air heating ensures smooth, firm seals without damaging tube patterns, suitable for plastic and laminated tubes. Intelligent temperature control and integrated cooling maintain consistent sealing quality.

2.Flexible Multi-Station Design

9 configurable working stations with manipulators accommodate different tail-folding and sealing requirements, making the machine versatile for various tube types.

3.Precise Photoelectric Alignment & Orientation

High-precision sensors with ±0.2mm tolerance automatically detect tube orientation and eye marks, ensuring accurate positioning and professional sealing.

4.Intelligent Control & Safety Features

Integrated light, electric, and pneumatic system with “no tube, no fill,” low-pressure alarms, overload protection, and automatic shutdown for open doors or tube errors.

5.Efficient Tube Feeding & Adjustment

Motorized tube storage with adjustable height and external reversal feeding system enables smooth, organized, and convenient tube loading.

6.Automated Filling, Coding & Tail Cutting

Anti-drip filling nozzles, automatic batch/date printing, and waste-cutting manipulators enable precise filling, clean product output, and professional tail sealing shapes.

Technical Parameters

| 1 | Filling volume | 50-270ml/unit (Adjustable) |

| 2 | Filling accuracy | ≦±1﹪ |

| 3 | Capacity | 2400-3000unit/hour, Adjustable |

| 4 | Tube diameter | Φ25-50 mm |

| 5 | Tube length | 50-200mm |

| 6 | Hopper volume | 40L |

| 7 | Power | 380V/220V (Optional) |

| 8 | Air pressure | 0.4-0.6 MPa |

| 9 | Equipped motor | 1.1KW |

| 10 | Machine power | 5kw |

| 11 | Inner wind motor | 0.37kw |

| 12 | Convulsions motor | 0.37kw |

| 13 | Dimension | 1950×760×1850(mm) |

| 14 | Weight | About 750 Kg |

Working Process of a Inner Heating Tube Filling Sealing Machine

- Tube Feeding: Empty tubes are automatically arranged and oriented for consistent feeding.

- Positioning & Centering: Tubes are precisely positioned and aligned at the filling station.

- Accurate Filling: A piston pump dispenses a precise and consistent product volume into each tube.

- Tube Tail Folding: The tube tail is folded into a preset shape before sealing.

- Inner Heating Sealing: As the core process, a metal heating head is inserted into the tube tail to apply internal heat.

- Pressing & Sealing: Pressure is applied to fully seal the heated tube tail.

- Cooling & Forming: The sealed area is cooled to ensure strong and stable sealing.

- Coding / Printing: Production date, batch number, or other codes are applied.

- Finished Product Discharge: Completed tubes are discharged and transferred to the next process.

How Tube Filling and Sealing Machines Reduce Product Waste?

Automatic inner heating tube filling sealing machine are designed to maximize efficiency while minimizing material loss. Their precise dosing systems accurately dispense creams, gels, or pastes into each tube, ensuring consistent fill volumes and eliminating overfilling, leakage, or spillage. This level of control not only improves product uniformity but also significantly reduces wasted product during production.

In addition, the automated sealing and tail-trimming process limits material waste at the tube end. Excess plastic is cut cleanly, and a tight, reliable seal is formed every time, preventing product residue and packaging defects. This waste-reduction capability is particularly valuable in cost-sensitive industries such as cosmetics, pharmaceuticals, and food processing, where raw material efficiency directly impacts profitability.

What Maintenance Requirements Do Inner Heating Tube Filling Sealing Machine Have?

- Regular Cleaning: Clean all product-contact parts after each run to prevent contamination.

- Lubrication: Maintain pneumatic and moving components according to manufacturer guidelines.

- Sealing Inspection: Check heating units and cutting parts for wear or residue buildup.

- Calibration: Periodically verify sensors and control system accuracy.

- Preventive Checks: Inspect hoses, seals, and electrical connections to avoid leaks and downtime.

A simple routine maintenance plan ensures stable operation, longer service life, and consistent sealing quality.