In the increasingly competitive packaging industry, bottling lines have become indispensable solutions for manufacturing sectors such as beverages, food, daily chemicals, cosmetics, and pharmaceuticals. The bottling system optimizes production processes, enhances efficiency, ensures high-quality product manufacturing, and meets enterprises’ diverse production needs alongside growing market demands. Therefore, understanding bottling line technology is essential. This guide will cover what a bottling line is, the specific machinery it includes, its workflow, applications, and key factors to consider when selecting a filling line. We hope the following information proves helpful.

What Is a Bottling Line?

The bottling line is used to fill bottles with various fluid liquids and semi-fluids, including liquids, pastes, sauces, and those containing particulate matter. It is also known as a filling line.it can be categorized into semi-automatic filling lines ( suited for low-volume production) and fully automatic filling lines ( suited for high-volume production). It is applicable to industries such as food, pharmaceuticals, chemicals, lubricants, coatings, cosmetics, edible oils, health supplements, pharmaceutical raw materials, veterinary drugs, and pesticides.

What Is a Bottling Line Used for?

The Bottling lines can fill various liquids and semi-liquids, and are used in a wide range of industries, including the following:

1.Beverage Industry

- Water: Purified water, mineral water, sparkling water

- Soft Drinks: Carbonated drinks, juice, tea, sports and energy drinks

- Alcoholic Beverages: Beer, wine, spirits, Baijiu, RTD cocktails

- Dairy Drinks: Milk, yogurt drinks, probiotic beverages

2.Food Industry

- Condiments: Edible oil, soy sauce, vinegar, cooking wine, sauces

- Food Products: Honey, jam, ketchup, canned foods, liquid/powder seasonings

- Specialty Foods: Olive oil, sesame oil, fermented liquids

3.Daily Chemical & Personal Care

- Cleaning Products: Laundry detergent, dishwashing liquid, toilet cleaner

- Personal Care: Shampoo, body wash, skincare products, toothpaste, hand soap

4.Pharmaceutical & Medical

- Pharmaceuticals: Oral liquids, syrups, injectables, eye drops, ointments

- Medical Supplies: Disinfectant alcohol, iodine solution, saline

5.Chemical & Agrochemical

- Industrial Chemicals: Lubricants, oils, paints, resins, adhesives, solvents

- Agrochemicals: Pesticides, herbicides, liquid fertilizers

What Equipment Is Used in Bottling?

1.Bottle Unscrambler

The automatic bottle unscrambler consists of a bottle elevator, rotary table, bottle arranging system, and electrical control cabinet. Loose bottles are lifted, guided through the rotary plate and conveyors, and automatically aligned on the belts. With a compact design and stable operation, the machine is easy to use and delivers reliable performance.

2.Bottle Rinsing Machines

Inverting bottle rinsing machines use air, water, or cleaning solutions to remove contaminants from containers before filling. Soft-pad grippers securely hold bottles without scratching during inversion over the rinse basin. These machines are suitable for a wide range of glass and plastic containers.

2.Piston Filling Machine

The NP-VF Piston Filling Machine is an excellent piston filling equipment designed for dosing viscous liquids across various industries. It proves highly effective in the daily chemicals and cosmetics fields, food industry and pharmaceuticals for dosing thin and viscous liquid products like body lotion, cosmetic creams, emulsions, gels, hand soap, serums, shampoo, and detergents

3.Capping Machine

NP-LC Automatic Spindle Capping Machine is a flexible and efficient solution for bottle sealing. Designed to handle a wide range of cap types and sizes, it delivers precise and reliable capping performance.

3.Labeling Machine

This automatic labeling machine is suitable for round, flat, square, and tapered bottles used in food, cosmetic, and healthcare industries. It features a touch-screen control for easy operation, adjustable speed, and fault alarms. CE certified for EU compliance, the machine provides ±1 mm labeling accuracy and supports flexible bottle and label size adjustments.

4.Case Packing Machine

Automatically packs a preset number of bottles into cartons or plastic crates.

5.Carton Sealing Machine

Seals the lids of cardboard boxes and applies adhesive tape.

6.Palletizer

Automatically stacks the boxed products onto wooden or plastic pallets, forming neat stacks for easy forklift transportation and storage.

How Does a Bottling Company Work?

A bottling line company specializes in the research, development, and manufacturing of automated packaging equipment. It provides one-stop, customized solutions based on different products (such as sauces, pastes, liquids, etc.), container types, and production capacity requirements.

The complete production line includes a bottle unscrambler, bottle washer, filling machine, capping machine, labeling machine, carton erector, carton sealing machine, palletizer, and other auxiliary equipment. From design to manufacturing and assembly, the entire process is subject to strict quality control to ensure long-term stable operation and minimize equipment failure rates.

In addition, the company offers global installation and commissioning, operator training, technical maintenance, system upgrades, and continuous after-sales support, meeting the diverse needs of brand owners and equipment partners worldwide.

How Does a Fully Automatic Bottling Line Work ?

The fully automatic filling line mainly consists of several systems, including depalletizer, bottle washing, filling, capping, labeling, and so on. The following is its workflow:

1.Depalletizer

- Suction cups or grippers of the high-speed depalletizer automatically lift an entire layer of bottles, place them smoothly onto the conveyor, and stack empty pallets. Bottles are then single-filed and neatly conveyed to the next stage.

2.Empty Bottle Washing

- Bottle Washer: Contaminants inside the containers are removed using ionized water or other cleaning technologies, preparing them for the filling stage.

3.Precision Filling

- Empty containers are conveyed precisely under the filling nozzles.

- The nozzle aligns with the container, and the piston retracts to draw an exact volume of liquid from the storage tank into the cylinder.

- The valve switches, and the piston pushes forward, injecting the entire liquid volume into the container.

- The filling nozzle lifts, and the filled container moves forward. The next empty container arrives, repeating the process.

4.High-Precision Capping

- Filled bottles are immediately fed into the capping machine.

- A lifting mechanism raises the bottle so the mouth contacts the cap.

- The cap feeding system automatically organizes and sorts caps (from a vibratory bowl or elevator) and delivers them to the capping head via magnetic tracks or chutes.

- The capping head applies the cap (screw cap or roll-on aluminum cap) at preset torque and speed. Torque data is continuously fed back to the control system to ensure a secure seal.

5.Labeling / Coding

- Labeling Machine: Automatically picks, applies adhesive (or uses self-adhesive labels), and accurately attaches labels to the designated position on the container.

- Coding Machine: Retrieves date and batch information from the control system and prints it dynamically on the bottle body or bottom using laser or inkjet technology.

6.Case Packing

- Bottles are grouped according to preset quantities (e.g., 6, 12, 24 bottles) and automatically grabbed or pushed into open cartons by robotic arms or flexible packing mechanisms. Cartons are automatically erected from flat cardboard, formed, and sealed at the bottom.

7.Carton Sealing

- Carton flaps are folded automatically and sealed using hot melt glue or adhesive tape.

8.Palletizing

- Robots use vision systems to locate cartons and, with grippers, automatically stack them onto pallets in preset patterns (e.g., 5×5) efficiently and neatly. Once stacking is complete, an automatic stretch wrap machine tightly secures the palletized products.

What Are Examples of Bottling?

Npack specializes in liquid bottling lines, providing customers with one-stop customized packaging solutions. Our machines are exported to the United States, Canada, Spain, Bulgaria, Poland, Portugal, Indonesia, the Philippines, Egypt, Romania, and many other countries. Below are some examples of bottling lines:

1.Wine Bottling Line

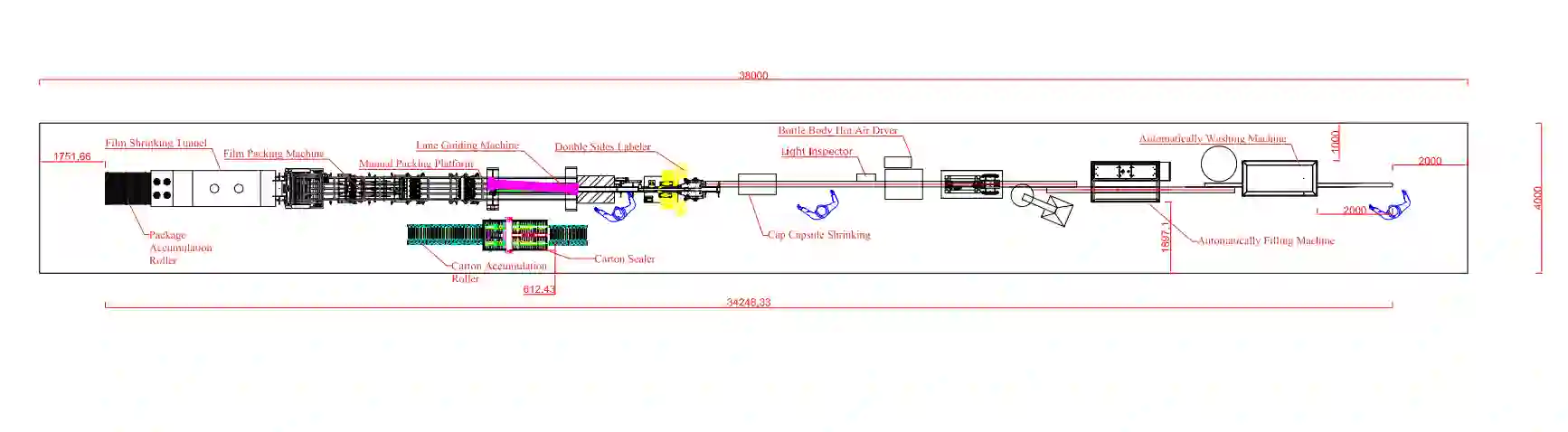

Project Background:

In 2020, based on the specific requirements of a customer in Uzbekistan, we delivered three complete vodka filling lines. The solution was designed to accommodate more than ten different glass bottle types, significantly increasing the customer’s vodka filling capacity.

Filled Product: Vodka

Solution:

We supplied a fully automatic production line integrating a bottle washing machine, piston filling machine, bottle hot-air drying system, optical inspection unit, cap sealing heat shrink machine, and other auxiliary equipment.

Project Results:

The project achieved efficient and stable end-to-end automated production, substantially improving filling efficiency and packaging quality, and successfully meeting the customer’s capacity expansion objectives.

2.Daily Chemical Bottling Line

Project Background:

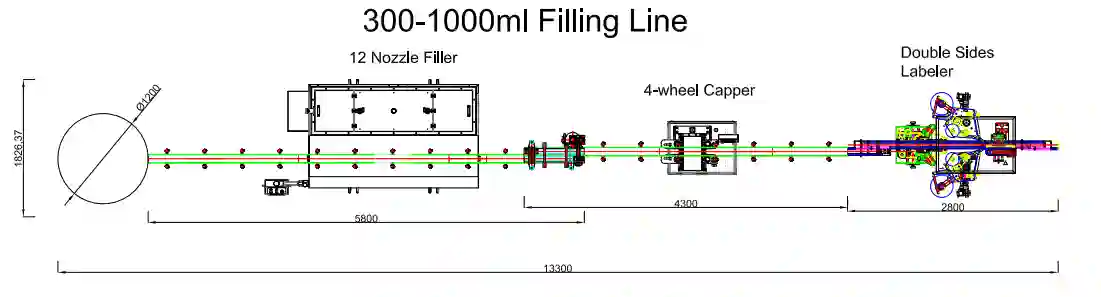

In 2025, we supplied a laundry detergent filling production line for a customer in the United States, aimed at enhancing automation and overall production efficiency.

Filled Product:

Laundry detergent, 300 ml–1000 ml

Key Requirements:

High-precision filling, stable and reliable capping with consistent sealing torque, and full-process quality monitoring and traceability.

Solution:

An integrated fully automatic line featuring a 12-head filling system with anti-drip design, a 4-wheel capping machine with precise torque control, and a double-side labeling machine, enabling seamless end-to-end automation.

Project Results:

Production speed and filling consistency were significantly improved, while product loss and labor dependence were reduced. The solution fully met the customer’s upgraded requirements for both efficiency and product quality.

3.Sauce Bottling Line

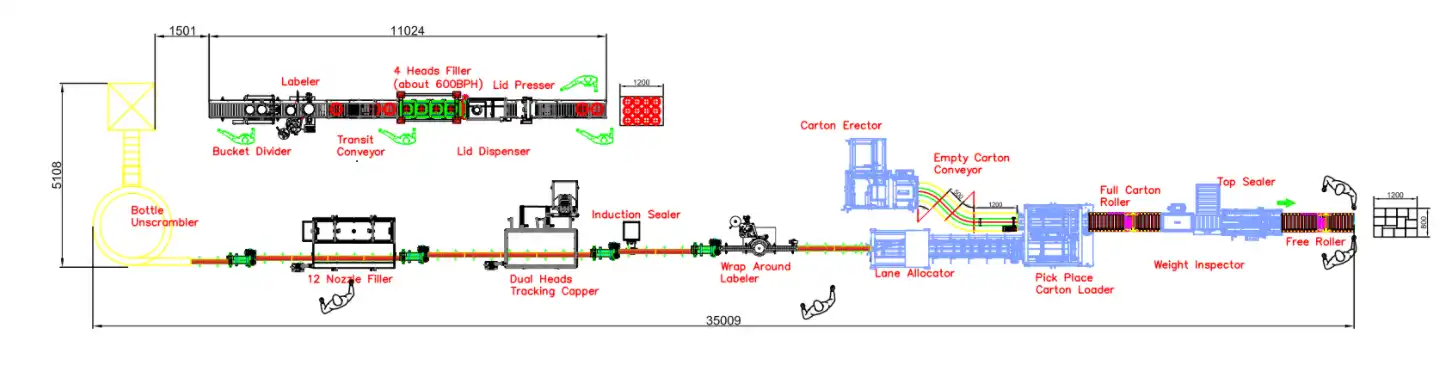

Project Background:

This project was custom-designed for a new factory of an Italian customer, fully adapted to their required production capacity and workshop layout.

Filled Product:

Suitable for various types of sauces

Key Requirements:

High-efficiency filling, reliable sealing, automatic checkweighing, and carton sealing.

Solution:

A customized integrated production line incorporating a 12-head filling machine, bottle elevator, tracking capping machine, aluminum foil induction sealing machine, labeling machine, checkweigher, and other synchronized equipment.

Project Results:

The production line operates stably with high filling accuracy and reliable sealing performance, ensuring the customer’s new factory is successfully commissioned and put into operation.

4.Oil Bottling Line

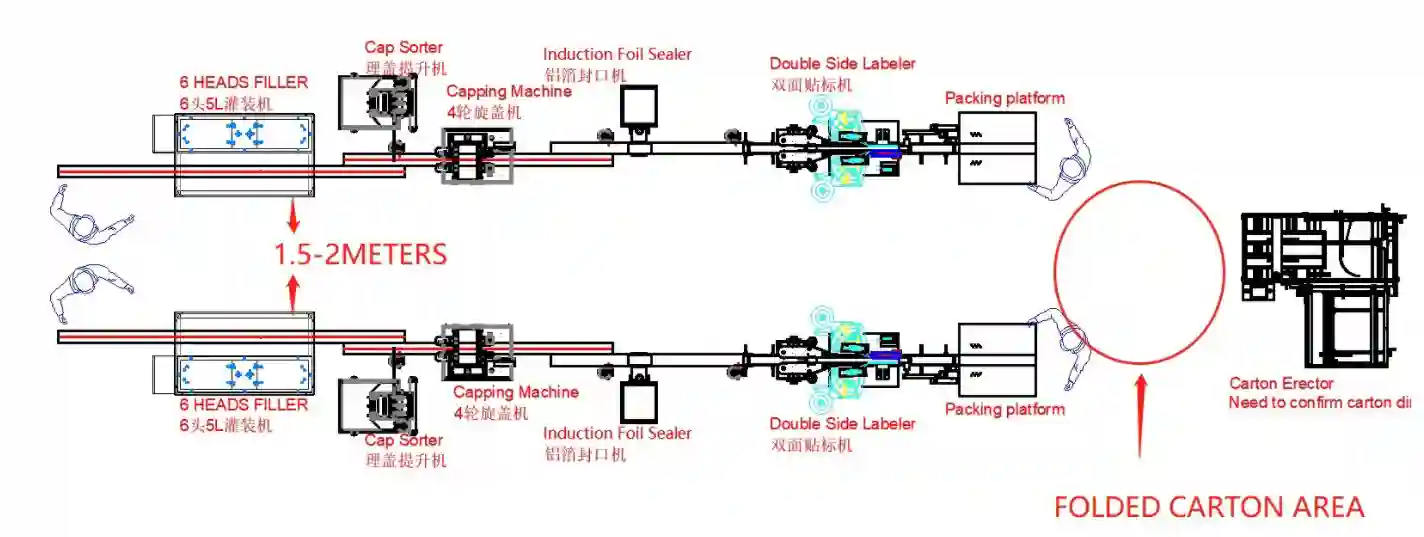

Project Background

To support a U.S. customer’s new factory, we delivered a customized filling solution optimized for capacity planning and space utilization.

Filled Product

5-liter lubricating oil

Solution

An integrated automatic line including a 6-head high-precision filling machine, automatic cap sorting and elevator system, 4-wheel capping machine, and double-side labeling machine. The compact, modular layout adapts easily to the customer’s workshop.

Project Results

The line operates stably and efficiently, ensuring accurate filling and reliable sealing. The project enabled smooth commissioning of the new plant and achieved simultaneous upgrades in productivity and product quality.

Conclusion

Modern bottling lines are essential for improving efficiency, accuracy, and packaging quality across industries such as beverages, food, daily chemicals, pharmaceuticals, and industrial liquids. A well-designed bottling line integrates filling, capping, labeling, and packaging into a stable, automated system tailored to specific production needs.

With extensive global project experience, Npack provides customized, one-stop bottling line solutions that help customers achieve reliable operation, higher productivity, and consistent product quality—whether for new factory setups or production upgrades.