The 50L-300L Weight Liquid Filling Machine is a semi-automatic high-precision system designed for accurate net weight filling of drums and barrels. Using advanced weighing control technology, it ensures precise dosing through intelligent fast and slow dual-speed filling.

Built with durable SUS304 or SUS316 stainless steel , this machine is ideal for filling various liquids—including coatings, resins, lubricants, and edible oils. It achieves an impressive accuracy of ≤0.05% F.S. and can handle 30–60 barrels per hour, ensuring both efficiency and precision.

With optional explosion-proof configurations (ExdIIBT6), it is widely used in the chemical and food industries, providing reliable, safe, and efficient filling for medium- to large-volume liquid production lines.

50L-300L Weight Liquid Filling Machine Features

1.Advanced PLC & Touch Screen Control

Equipped with PLC programmable controller and 7-inch color touch screen, offering safe, reliable, and intuitive operation. Operators can easily adjust parameters, manage 30 stored formulas, and switch between net weight and gross weight filling modes.

2.High-Precision Weighing System

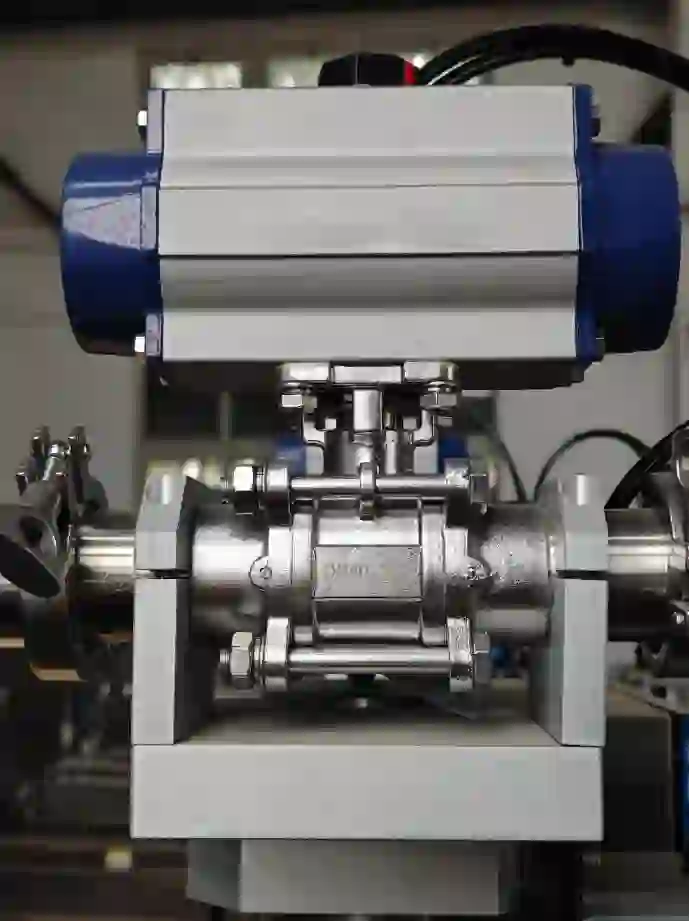

Utilizes weighing sensors and Schneider control system to ensure precise filling. Fast and slow speed profiling adapts to liquid characteristics, including foam-free or lightly foaming products, ensuring consistent accuracy.

3.Automated Nozzle & Drum Handling

The filling nozzle automatically lifts when not inserted or when the target weight is reached. The bunghole alignment device ensures accurate barrel positioning, while no barrel, no filling enhances safety and efficiency.

4.Anti-Drip Professional Nozzle

Designed with anti-drip professional nozzle, preventing drips and contamination, maintaining a clean production environment, and reducing material waste.

5.Intelligent Monitoring & Safety

Features automatic tare deduction, overfill alarm, differential pressure protection, and anti-collision sensors to prevent errors. Dual-display windows show filling quantity, barrel count, and cumulative totals.

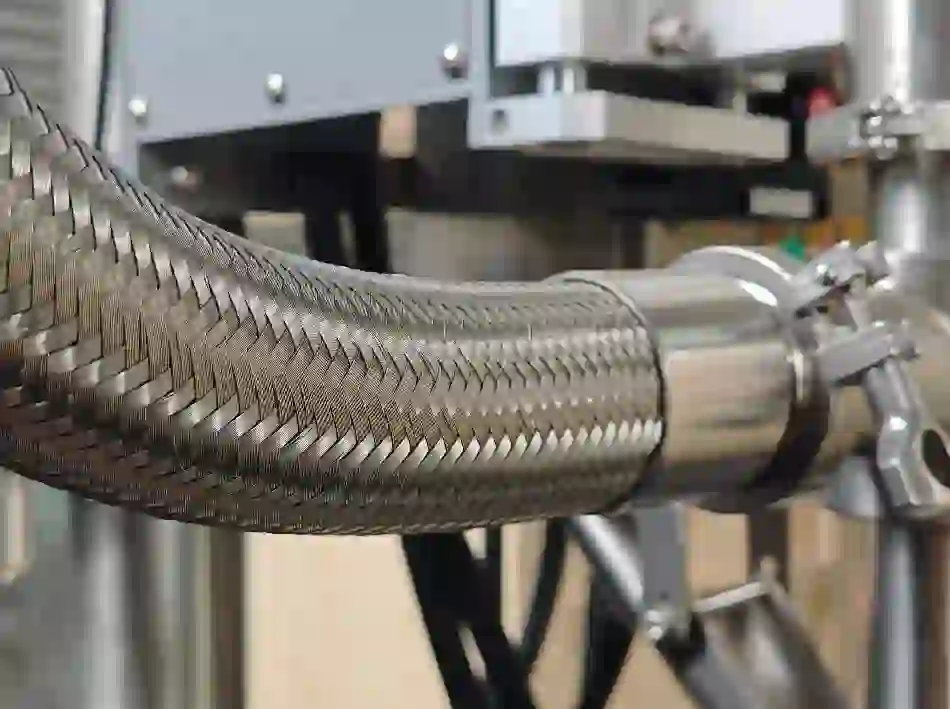

6.Convenient Maintenance & Cleaning

Quick-coupling filling pipes and nozzles simplify disassembly and washing, meeting hygiene and industrial standards while reducing downtime.

Technical parameters

| 1 | Accuracy | ±0.1% |

| 2 | Weighing Range | 20-300kg |

| 3 | Filling Speed | 40- 60pcs/hour |

| 4 | Air Supply | 150L/min |

| 5 | Power Supply | AC220V 50HZ |

| 6 | Dimension(mm) | 1220x870x1650 |

| 7 | Weight | 120 kg |

How Does the 50L-300L Weight Liquid Filling Machine Work?

The 50L–300L Weight Filling Machine operates on a net weight filling principle using a high-precision gravimetric system. During filling, integrated load cells continuously measure the actual weight of liquid entering the container. Once the preset target weight is reached, the system automatically stops filling, ensuring high accuracy and consistency regardless of liquid density or temperature variations.

Liquid is dispensed through controlled filling nozzles with adjustable flow rates, allowing stable filling of both low- and high-viscosity products. The entire process is managed by a PLC-based control system, which enables precise adjustment of filling weight, speed, and operating parameters. Containers are accurately positioned under the nozzles via a coordinated handling system, ensuring reliable and efficient operation throughout the filling cycle.

What Process Control Features Are Available in the 50L-300L Weight Liquid Filling Machine?

The 50L–300L Weight Filling Machine is equipped with an advanced PLC-based control system designed for high precision and operational efficiency. Through a user-friendly interface, operators can easily adjust key parameters such as target filling weight, dispensing speed, and filling sequence to suit different products and container types, including drums, pails, and IBCs.

In addition, the system continuously monitors fill weight and product density in real time using integrated load cells. This intelligent process control allows immediate detection and correction of deviations, ensuring consistent results across batches. With data logging and feedback functions, the machine supports quality control, traceability, and regulatory compliance, making it ideal for applications that demand strict accuracy and repeatability.

What Affects Filling Accuracy, and How Is Precision Ensured?

Main Factors:

- Product properties: Viscosity, air content, and temperature changes affect product density.

- Calibration status: Uncalibrated load cells or flow meters may cause accuracy drift.

- Air supply stability: Fluctuating air pressure leads to inconsistent valve response.

- Operation & alignment: Misaligned containers or filling nozzles can cause spillage or false signals.

- Installation environment: Vibration and airflow may interfere with weighing sensors.

Accuracy Control Measures:

- Regular calibration with certified standard weights.

- Dual-speed filling control (fast filling + slow topping) for precise final weight.

- Stable, dry compressed air supply.

- Solid, vibration-free machine installation.