The 10kg-30kg Weight Liquid Filling Machine is a high-precision filling system specially designed for medium-capacity liquid packaging. Using an advanced weighing control system, it ensures accurate net weight dosing with dual-speed filling to achieve both speed and precision.

Operators only need to place the empty pails or containers on the conveyor, and the sensor will automatically stop, position, and start filling. Once the target weight is reached, the valve closes and the filling nozzle lifts automatically, preventing overflow and dripping.

Widely used in food, chemical, oil, and pharmaceutical industries, this machine is ideal for various liquid materials—from viscous and foamy to corrosive types—delivering stable performance, clean operation, and reliable productivity for modern production lines.

10kg-30kg Weight Liquid Filling Machine Features

1.High-Quality Construction

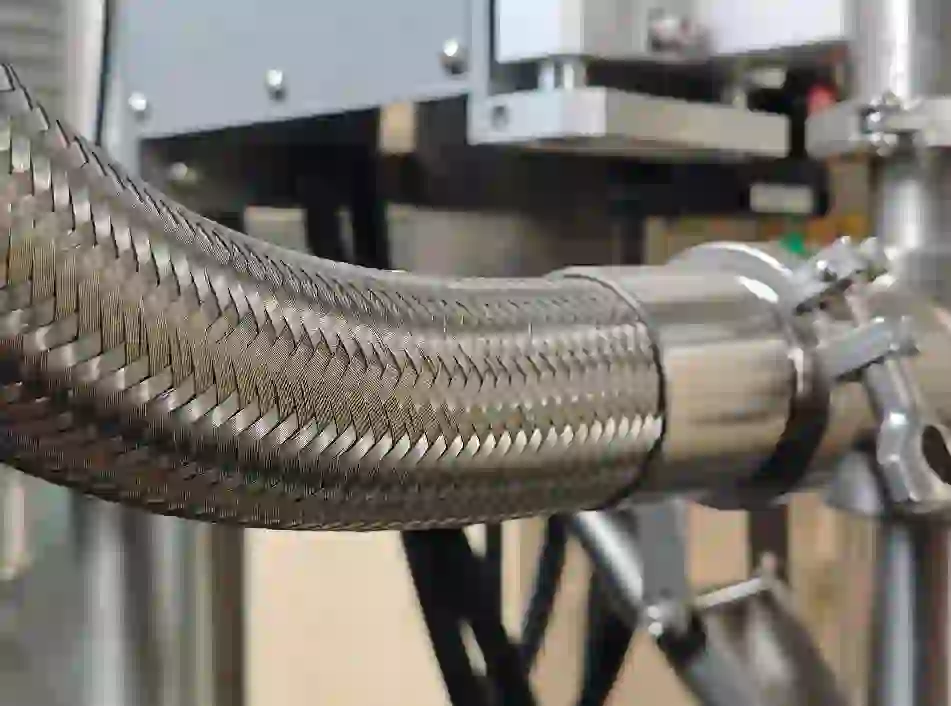

10kg-30kg weight liquid filling machine body is made entirely of SUS304 stainless steel, with food-grade SUS316L filling nozzles and flow pipelines, ensuring durability, hygiene, and compliance with food and chemical industry standards.

2.Adjustable and Safe Operation

Filling nozzle height and position limit devices are fully adjustable, improving operational efficiency, reducing labor, and ensuring reliable, precise filling.

3.Precision Net Weight Filling

10kg-30kg Weight liquid filling machine equipped with electronic digital load cells, the machine provides accurate weight filling for various liquid products, maintaining consistency across batches.

4.Flexible Container Compatibility

Suitable for pail or can filling of rigid containers ranging from 10 kg to 30 kg, accommodating diverse production needs.

5.Single or Multi-Head Options

Available in single or multiple head configurations depending on the required filling speed and production capacity.

6.User-Friendly Control Interface

Operators can access all machine functions, including scale calibration, set points, and diving nozzle control. Stored recipe data allows one-key loading for quick setup changes.

7.Accurate Filling Profiles

Supports fast fill/slow fill (bulk and dribble) operations to ensure precise filling on large containers, minimizing spills and waste.

8.Convenient Container Handling

Roller conveyor beds allow easy positioning of pails or cans under the filling nozzles, and operation can be performed via start button or foot pedal, making workflow smooth and ergonomic.

Technical parameters

| 1 | Fill Range | 10-30kg |

| 2 | Accuracy | ≤0.1% |

| 3 | Speed | 120-150 Pails/hour |

| 4 | Barrel | ≤Φ350xh500 |

| 5 | Power | AC220/50Hz |

| 6 | Air | 0.4-0.8mpa |

Operation Process of 10kg–30kg Weight Liquid Filling Machine

After the machine is powered on, the operator manually places the empty barrel onto the weighing platform. The platform enables quick positioning and accurate alignment of the barrel opening. Once the system detects the barrel in place, the filling nozzle automatically descends and precisely inserts into the barrel mouth.

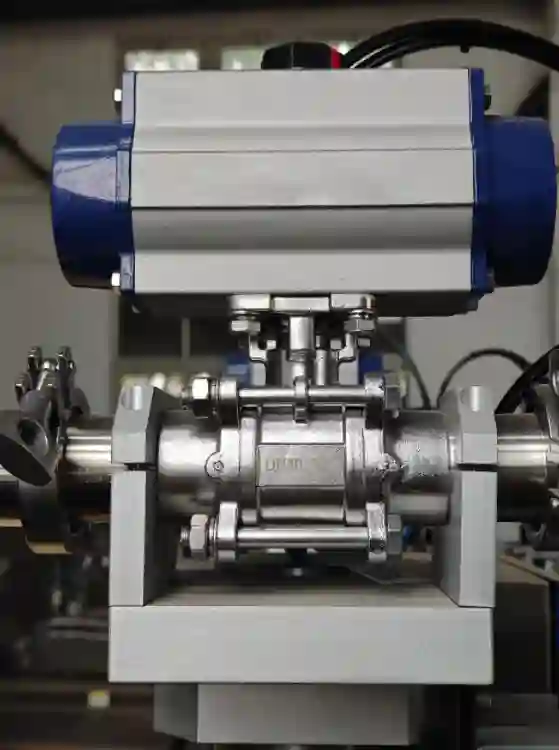

The machine then performs automatic tare deduction to ensure filling accuracy. Upon confirmation, the filling nozzle and ball valve open automatically, and the filling process begins. To achieve both high efficiency and precision, the machine adopts a three-stage filling mode with large, medium, and small flow rates, allowing smooth transition from fast filling to fine dosing.

When the preset target weight within the 10kg–30kg range is reached, the system immediately stops filling, and the nozzle rises above the barrel mouth to prevent dripping or overflow. Finally, the filled barrel is manually capped and stacked, completing the entire filling cycle efficiently and accurately.

Key Considerations for Selecting a 10kg–30kg Weight Liquid Filling Machine

- Liquid Type: Evaluate the viscosity and properties of the liquid, and confirm whether it is for food, cosmetic, chemical, or pharmaceutical use to ensure compatibility and accuracy.

- Production Capacity: Define your required output per hour or per day. 10kg–30kg machines are ideal for medium-scale production.

- Filling Accuracy: Ensure the machine meets your weight accuracy and consistency requirements.

- Filling Speed: Match the machine’s filling speed with your production efficiency targets.

- Automation Level: Choose the appropriate level of automation, such as PLC and touch screen control, to suit your operation.

- Maintenance & Cleaning: Select a machine with a simple structure for easy cleaning and routine maintenance.

- Budget: Balance performance and features with your available investment to achieve the best cost-performance ratio.