Automatic Horizontal Vial Labeling Machine is designed for precise, high-speed labeling of round or tubular containers such as ampoules, vials, tubes, pens, and small bottles, . It is widely used in pharmaceutical, cosmetic, food, daily chemical, and electronics industries, ensuring smooth, accurate, and efficient labeling.

Featuring a horizontal conveying and labeling structure, the machine provides excellent stability and labeling precision, effectively avoiding bubbles and wrinkles. It supports various label types including barcode, QR code, transparent, and electronic supervision labels.

Optional ribbon coder or inkjet printer allows simultaneous printing of batch numbers and production dates, achieving labeling–coding integration and improving overall packaging efficiency. Compact, reliable, and user-friendly, this labeling machine is ideal for high-speed production lines requiring precision and consistency.

Horizontal Vial Labelling Machine Main Feature

1.High-Speed Horizontal Labeling for Unstable Cylindrical Bottles

Optimized for unstable or round bottles, the horizontal conveying system ensures smooth, precise label application without wrinkles or misalignment, supporting high-speed production up to 100 bottles per minute.

2.Precision Control with Advanced Sensors

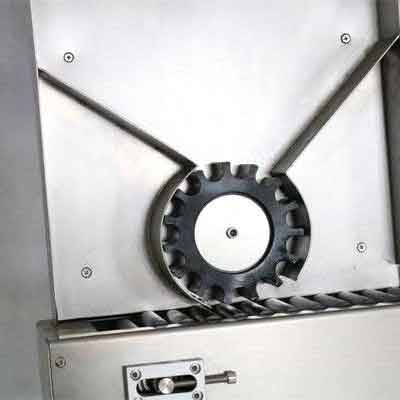

Equipped with photoelectric detection and servo-driven mechanisms, the machine guarantees accurate label placement, prevents missing labels, and automatically adjusts for different bottle sizes and shapes.

3.Flexible Labeling for Various Containers

Horizontal vial labeling machine supports a wide range of product diameters and label dimensions. Adjustable conveyor speed, height, and angle allow quick changeovers and seamless integration into diverse production lines.

4.Durable and Hygienic Construction

Built with 304 stainless steel and high-grade aluminum, the structure meets GMP standards, ensuring long-term durability, easy cleaning, and safe operation.

5.User-Friendly Operation and Smart Interface

Touchscreen controls and intuitive PLC interface simplify operation, parameter setting, and production monitoring, reducing errors and improving workflow efficiency.

6.Consistent Quality with Minimal Waste

High labeling accuracy ensures smooth, wrinkle-free results and maintains product quality, while reducing label and material waste for cost-effective production.

7.Reliable Integration for Automated Lines

Designed to work seamlessly with upstream and downstream machinery, this horizontal vial labeling system can be combined with filling, capping, and packaging lines for complete automation.

Technical Parameters

| 1 | Model | NP-HL |

| 2 | Drive | Step Motor Driver |

| 3 | Labeling Speed | 100pcs/min |

| 4 | Bottle Height | 10-30 mm |

| 5 | Label Size | Width: 10-90mm Length: 15-100mm |

| 5 | Precision | ±1mm |

| 6 | Label Roll | Max: 300mm |

| 7 | Label Core | Stander: 75mm |

| 8 | Machine Size | 1800*600*1400mm |

| 9 | Weight | 220Kg |

| 10 | Power | AC 110/220v 50/60Hz 500W |

How Do Label and Product Sensors Work in Horizontal Vial Labeling Machines?

Equipped with a warning system for insufficient or broken labels.

Ensures no labeling occurs if there is no bottle present.

Stops labeling and triggers an automatic warning if there are no labels available.

Provides an automatic warning when the ribbon is missing.

Features a label sensor compatible with both paper and opaque labels, delivering reliable detection for a wide range of labeling materials.

Includes a product sensor with opaque detection capabilities, ensuring precision even with transparent or low-contrast containers.

Can These Labelers Be Integrated Into Automated Packaging Lines or Used as Stand alone Machines?

This horizontal pharmaceutical bottle labeling system is excellently designed and can be integrated with bottle washing machines, filling machines, capping machines, and packaging lines to achieve fully automated production. Npack customizes the machines based on production volume, bottle type, and facility size to suit different production layouts – the specific length may vary depending on the chosen configuration. Whether you need a standalone operation for small-batch production or integration into a fully automated packaging line, this machine easily adapts to your workflow and space requirements.

What types of label sensors can be used for different label materials(clear, metallic, color)?

Compatible Label Sensors for Diverse Label Materials

To ensure precise label detection regardless of the type of label being used, the machine supports a range of sensor options tailored for different materials:

- Clear Label Sensors: Specialized sensors such as optical or capacitive types are recommended for transparent or clear labels, which are often difficult for standard sensors to detect.

- Metallic Label Sensors: For reflective or metallic labels, photoelectric or inductive sensors are suitable, as they can accurately identify the unique reflective properties of metallic surfaces.

- Color Label Sensors: When working with colored or opaque labels, conventional optical sensors are ideal for reliable detection and consistent label application.

Selecting the appropriate sensor type allows for seamless changeover between label materials while maintaining high accuracy and efficient operation.

What types of printing and coding options can be integrated into a horizontal vail labeling machine?

Flexible Printing and Coding Integrations

To further enhance traceability and meet diverse production needs, the horizontal vial labeling machine offers multiple integrated printing and coding solutions. Depending on your requirements, you can choose from:

- Hot Stamp Coders: Ideal for imprinting lot numbers or production dates directly onto labels for compliance and batch tracking.

- Thermal Transfer Overprinters: These support not only clear lot and date coding, but also barcodes and custom graphics, enhancing both functionality and branding.

- Imprint Detection Systems: Ensure every label receives a code—if an imprint is missing, the system automatically identifies and alerts for immediate action.

This level of integration supports efficient, error-free production while accommodating regulatory and quality assurance standards.