The Automatic Round Bottle Labeling Machine is designed for precise and efficient wrap-around labeling of cylindrical bottles across industries such as food, beverage, cosmetics, pharmaceuticals, and chemicals. Featuring an advanced PLC control system with a user-friendly touch screen interface, it delivers easy operation, stable performance, and quick parameter adjustment for various production requirements.

With a labeling accuracy of ±1mm and speeds ranging from 60 to 200 bottles per minute, this machine ensures high efficiency and consistent labeling results even in high-speed production lines. The servo or stepper motor drive system, combined with a high-sensitivity photoelectric sensor, guarantees accurate label positioning and smooth application for both single and double labels.

Built from SUS304 stainless steel, the automatic labeling machine provides excellent durability, hygiene, and long-term reliability. Optional configurations include vision inspection, label usage detection, and adjustable machine height to meet different production needs. Certified with CE standards, the machine ensures compliance with EU safety and quality regulations, making it a dependable choice for modern packaging lines.

Automatic Round Bottle Labeling Machine Features

1.User-Friendly Operation

Touchscreen interface with multilingual support makes setting parameters, monitoring production, and switching products quick and intuitive.

2.Precise Labeling

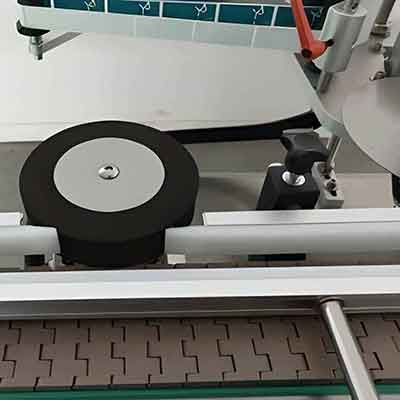

High-quality sensors and servo-driven mechanisms ensure accurate placement of labels on round bottles with no wrinkles or misalignment.

3.Automatic Bottle Handling

Integrated bottle separation and detection systems prevent collisions or misfeeds, ensuring smooth and continuous labeling.

4.Fast Changeover

Adjustable labeling heads and quick-access settings allow rapid transition between bottles of different sizes or shapes without tools.

5.High-Speed Production

Designed for high-efficiency operation, the machine maintains consistent labeling accuracy even at maximum production speeds.

6.Safety & Error Prevention

Automatic pause or alarm activates when bottles are missing or labels run out, minimizing waste and reducing operator intervention.

7.Durable Construction

Made from food-grade stainless steel, the machine is corrosion-resistant, easy to clean, and fully compliant with GMP standards.

Technical Parameters

| 1 | Dimension | 2100(L)×1150(W)×1300(H)mm |

| 2 | Capacity | 60-200 pcs/min |

| 3 | Bottle Height | 30-280mm |

| 4 | Bottle Diameter | 20-120mm |

| 5 | Label Height | 15-140mm |

| 6 | Label Length | 25-300mm |

| 7 | Accuracy | ±1mm |

| 8 | Roll inside Diameter | 76mm |

| 9 | Roll Outside Diameter | 420mm |

| 10 | Power Supply | 220V 50/60HZ 1.5KW |

How Does a Automatic Round Bottle Labeling Machine Work?

Labeling Process:

- Bottles are conveyed from the filling line to the bottle separation unit.

- The separator spaces the bottles evenly, allowing sufficient time for accurate labeling.

- A product sensor detects each incoming bottle.

- Once detected, the signal is sent to the PLC, which activates the pneumatic cylinder to start the labeling action.

- The label is applied to the bottle and firmly pressed to ensure proper adhesion.

- After labeling, the cylinder returns to its original position, and the conveyor moves the labeled bottles to the next stage of the production line.

How Does the Machine Ensure Accurate Label Application?

Labeling precision is achieved through a combination of rigid mechanical design and advanced control technology. The machine features a solid, heavy-duty structure that minimizes vibration and maintains stability during operation, while remaining easy for operators to use. A high-performance drive system controlled by an advanced microprocessor enables fast, smooth, and highly accurate movement of both the labeling head and the label feed mechanism. In addition, the label application head is powered by a high-torque servo motor, allowing precise control over speed and positioning. Together, these elements ensure consistent, accurate label placement, even in high-speed, high-volume production environments, delivering reliable and repeatable labeling results.

Are There Additional Labeling Machines Available for Different Container Shapes and Sizes?

Flexible Labeling Solutions for Various Containers

In addition to fully automatic round bottle labeling machines, a wide variety of equipment is available to meet diverse customer needs, from small pharmaceutical bottles and flat bottles to oval containers, large cans, or irregularly shaped containers. Suitable labeling solutions exist for almost all applications, including:

Semi-automatic Labeling Machines

Ideal for small-batch production, offering precise operational control and quick changeovers.

Tabletop Labeling Machines

Compact and space-saving, suitable for businesses with low production volumes; can handle round, flat, or oval containers and can be equipped with date or batch number coding functions.

Automatic Double-sided Labeling Machines

One machine can label round, flat, square, and other containers, making it ideal for production lines handling multiple bottle types. Widely used in the food, daily chemical, and personal care industries.

For special packaging needs—such as uniquely shaped bottles or fragile materials—we also offer customized labeling systems and optional features, such as printers or vision inspection units, to ensure consistently high-quality labeling results.

With such a wide range of options, manufacturers can easily find a labeling machine that suits their container type, improves efficiency, and provides a clean and professional label appearance.

What Optional Accessories or Printers/Coders Are Available for This Applicator?

Optional Accessories and Printing Solutions

To enhance flexibility and functionality, this automatic round bottle labeling machine supports a wide range of optional accessories. It can be equipped with various coding and printing systems, including inkjet printers, thermal transfer printers, and hot foil coders. These systems enable efficient printing of batch numbers, production dates, expiry dates, barcodes, or variable data directly onto labels or product surfaces, improving traceability and regulatory compliance.

Additional optional configurations include label counting devices, missing-label detection systems, and transparent label sensors. These accessories can be selected based on specific production needs, helping optimize labeling accuracy, quality control, and overall line efficiency.