The Automatic Gravity Filling Machine is designed for non-viscous or low-viscous liquids such as water, juice, soy sauce, vinegar, air fresheners, and window cleaners. It supports a filling range of 100–5000ml with high accuracy of ±1%, making it ideal for food, beverage, chemical, and medical applications.

Equipped with PLC and touch screen control, the machine allows adjustable speed, customizable filling heads (8–24), and time-based filling for precise, efficient, and splash-free operation. Multiple bottles of different volumes can be filled simultaneously, ensuring high productivity.

Constructed with SUS304/316 stainless steel, it guarantees durability, hygiene, and corrosion resistance. Integrated with automatic grading, anti-drip slots, and conveyor systems, it can form a fully automated line with capping, labeling, and packing machines. CE and RoHS certifications ensure compliance with EU safety standards and market access, providing a reliable solution for modern liquid packaging lines.

Gravity Filler Machine-Reliable Solution for Low-Viscosity and Foamy Liquids

1.Durable and Hygienic Construction

Crafted from high-quality 304 stainless steel, with optional 316SS contact parts for stronger chemical resistance. For highly corrosive products, PVC or PP materials can also be customized to ensure long-term durability and compliance with GMP standards.

2.High Accurate and Consistent Filling

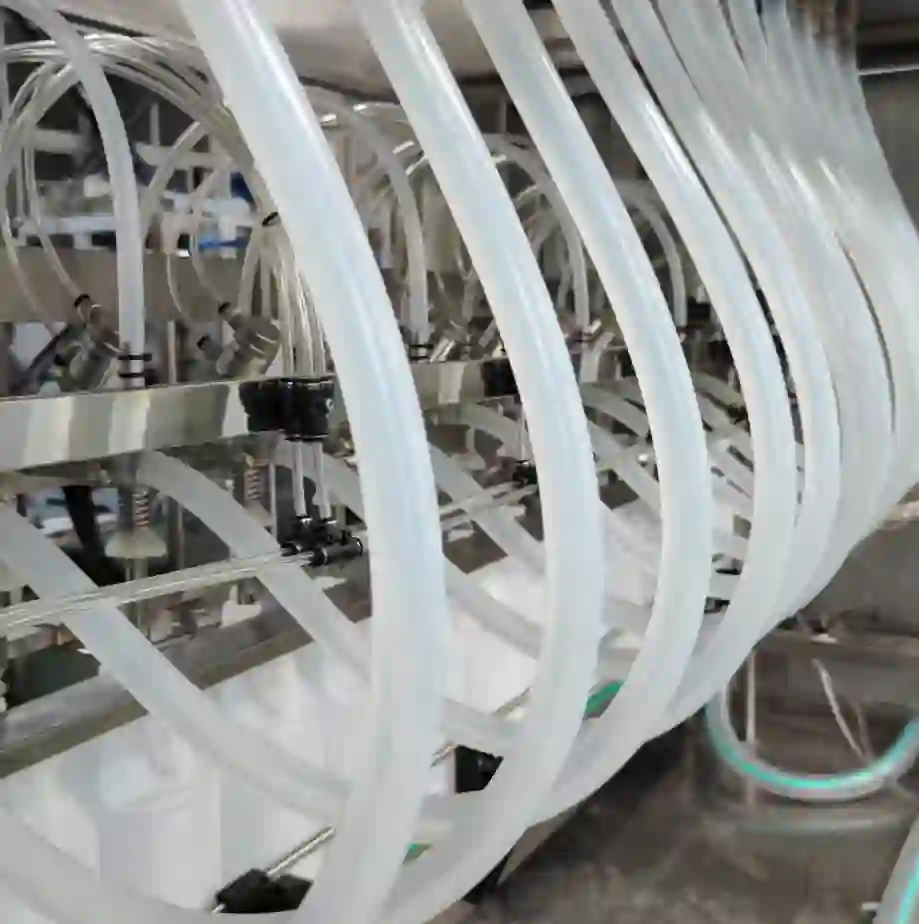

The gravity-based filling system uses time-controlled flow to ensure precise and consistent liquid levels in every bottle. Each nozzle is equipped with a bottle-neck positioning device for perfect alignment, minimizing splashes and overflow even with foamy liquids.

3.Ideal for Foamy or Thin Liquids

Specially designed for low-viscosity and easy-to-foam products such as soy sauce, vinegar, detergents, disinfectants, and beverages. Optional diving nozzles and anti-drip valves effectively eliminate foam and dripping, maintaining a clean production area.

4.Smart PLC Control with Touchscreen Interface

The system integrates a PLC intelligent control system with a bilingual touchscreen (Chinese/English), allowing operators to easily set fill volume, adjust parameters, and monitor production in real time. Features include “No bottle, no fill” safety detection and automatic error alerts.

5.Flexible Filling Range & Quick Changeover

Supports bottle sizes from 100ml to 5000ml, and can switch between different containers within minutes — no tools required. The modular design enables fast setup and adjustment for multi-format production lines.

6.Easy Cleaning & Maintenance

Quick-install fittings and tool-free disassembly make cleaning simple. The machine includes a liquid receiving tray to collect any residual drips, keeping the workspace sanitary and efficient.

7.High Efficiency & System Integration

With multiple filling heads (2–20 nozzles) available, the gravity filling machine achieves high-speed production and can be seamlessly integrated with capping, labeling, and sealing machines, forming a complete automated packaging line.

Technical Parameters

| Name | Automatic gravity Filling Machine |

| Measurement precision | ±0.5%-1% for 1L |

| Capacity | 800b/h-7200b/h |

| Voltage | 220VAC 50/60hz |

| Air pressure | 4~6kg/cm² |

| Air consumption | 1m/min |

| Power | 1000w |

How Gravity Filling Machine Works?

This filling machine operates on a gravity-based principle, providing efficient operation and reliable filling accuracy. Liquid is held in a hopper above the filling nozzles and flows naturally into containers when the valves open. Filling volume is controlled by preset timing, ensuring consistent results for every container. Once the set time is reached, the valves close and the next cycle begins.

This time-controlled gravity filling method is ideal for low-viscosity, free-flowing liquids. The smooth and gentle process is well suited for foamy products, reducing splashing and product loss.

With its advanced design, the gravity filling system offers both precision and flexibility for a wide range of liquid filling applications.

How Does Viscosity Affect the Gravity Filling Process?

This time gravity filling machine is suitable for filling easy-flowing or foamy liquids in industries such as pharmaceuticals, daily chemicals, food, and pesticides. Common applications include disinfectants, soy sauce, glass cleaners, vinegar, and liquid fertilizers.

Designed for low to medium-viscosity, uniform liquids without large particles, it performs best with water-like products rather than thick materials. A time-based volumetric filling system ensures consistent and accurate filling, with adjustable fill time to maintain precision even for foamy or free-flowing liquids.