The Semi Automatic Liquid Piston Filling Machine is designed for precise and efficient filling of various liquids and pastes, including honey, cream, shampoo, oil, and sauces. It features an adjustable filling range from 10ml to 5000ml, suitable for bottles, jars, and pouches.

Made of 304 stainless steel with optional 316L contact parts, the machine ensures food-grade safety and corrosion resistance. Powered by a pneumatic system, it delivers ±0.5% filling accuracy and supports heating, mixing, and anti-drip functions for high-viscosity materials.

Compact, durable, and CE certified, this semi automatic piston filler offers easy operation and low maintenance, making it ideal for food, cosmetics, chemical, and pharmaceutical industries. It provides reliable performance, consistent accuracy, and high productivity, making it the perfect solution for both small-scale and industrial production lines.

Semi Automatic Liquid Piston Filling Machine Feature

- High Filling Accuracy

Equipped with precision-engineered pistons and dosing heads, the machine guarantees consistent fill volumes with minimal product waste. The pneumatic shut-off and anti-drip nozzles further enhance filling precision and cleanliness. - Reliable Components

Core pneumatic parts adopt trusted brands such as SMC or FESTO, ensuring stable performance and long service life. SKF bearings and premium seals provide smooth mechanical operation and reduced maintenance needs. - Dual Working Modes

The filler supports both automatic and pedal-controlled modes, giving operators flexibility to adjust production speed and efficiency based on workload and product type. - Easy to Operate and Maintain

Featuring intuitive controls and a simple structure, the machine requires minimal operator training. Quick disassembly allows for easy cleaning and maintenance, ideal for applications that demand frequent product changes. - Compact and Space-Saving Design

Thanks to its compact size and lightweight structure, the machine can be easily integrated into existing production lines, making it suitable for workshops with limited space. - Safety and Quality Control

Built with emergency stop buttons and corrosion-resistant gaskets, the machine ensures operator safety while maintaining high production quality.

Technical Parameters

| Items | NP-S-06 | NP-S-12 | NP-S-25 | NP-S-50 | NP-S-100 |

| Filling Range | 5-60ml | 10-125ml | 25-250ml | 50-500ml | 100-1000ml |

| Air | 4-6kg/cm2 | 4-6kg/cm2 | 5-8kg/cm2 | 5-8kg/cm2 | 5-8kg/cm2 |

| Capacity | 0-30bottles/min | ||||

| Accuracy | 0.5% | ||||

| Voltage | AC220V 50/60Hz | ||||

| Power | 10W | ||||

| Net weight | 18.2kg | 20.1kg | 25.8kg | 30.5kg | 37kg |

| Gross weight | 21kg | 23kg | 29.7kg | 34.5kg | 41.5kg |

| Size | 844*290*731 | 911*290*731 | 1089*340*811 | 1180*340*828 | 1180*340*828 |

Main Components of a Semi Automatic Liquid Piston Filling Machine

1. Frame and Worktable

Built with a stainless steel structure, providing strong support, durability, and easy cleaning for daily operation.

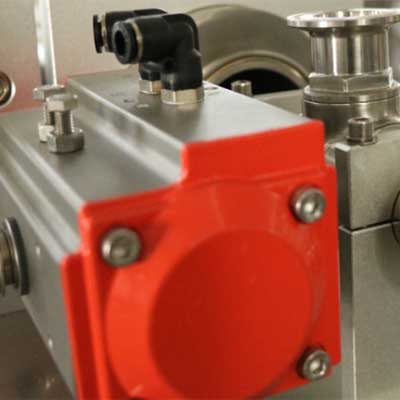

2. Piston Dosing Unit (Core Component)

Consists of a high-precision cylinder, piston, seals, and check valves to ensure accurate and consistent filling volumes. It is typically driven by a servo or stepper motor for precise control.

3.Product Tank / Hopper

Used to store the product to be filled. Made of food-grade stainless steel, with a simple design that allows easy cleaning.

4. Filling Nozzle

Different nozzle designs are available based on product characteristics. Immersion nozzles help reduce foaming, and optional anti-drip devices keep the filling area clean.

5. Control System

Operated via PLC or a control panel, allowing easy adjustment of filling volume and speed, with support for multiple parameter settings.

6. Lifting and Operation Components

The filling head height is adjustable to suit different container sizes. Foot pedal or two-hand start controls are used to ensure safe operation.

Semi Automatic Liquid Piston Filling Machine Working Process:

- Liquid or paste put into hopper manually

- Adjustable the right volume by hand wheel

- Put the container under the filling nozzle

- Step foot valve to start one-time filling

- Remove the full container and put the next container under the filling nozzles

- Repeat

Semi Automatic Liquid Piston Filling Machine Option Features

- servo motor driven is for option

- HMI is for option

- Mixing top hoppers

- 30L Double jacket hopper with heating

- Pressure top tank

- Rotary valve for food sauce with granular solid

- Ceramic pump cylinder is for option