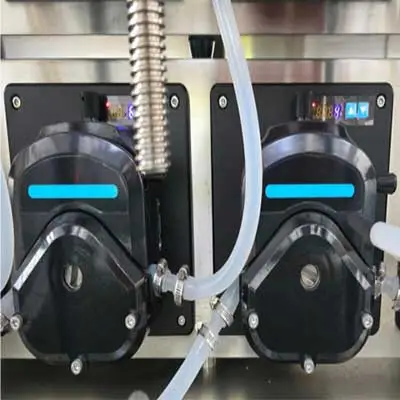

The Peristaltic Pump Filling Machine delivers accurate, leak-free filling for a wide range of liquids. Using advanced peristaltic pump technology, the liquid flows only through a food grade tube, preventing contamination and ensuring precise dosing for each container.

With servo motor control, PLC system, and a touch screen interface, operators can set filling volumes, adjust multi-head nozzles, and control production speed easily. Diving nozzles prevent foamy spillage, while electric eye sensors and chain conveyors ensure smooth, automated bottle transport.

Built from 304 stainless steel frames and 316L stainless steel contact parts, the machine guarantees hygiene, corrosion resistance, and easy cleaning. It handles essential oils, toners, perfumes, beverages, food, lab liquids and so on.

CE, and RoHS certifications ensure compliance with EU safety standards, making it a reliable, versatile, and user-friendly solution for modern production lines demanding precision, safety, and flexibility.

Peristaltic Pump Filler Main Feauture

1.Hygienic and Contamination-Free

The peristaltic pump filling machine ensures the liquid only contacts the inner wall of the disposable silicone tube, meeting CE hygiene standards and preventing cross-contamination between batches.

2.High Filling Precision

Driven by a PLC control system and digital microprocessor, it achieves filling accuracy within ±0.5%, suitable for pharmaceuticals, cosmetics, and laboratory liquids.

3.Easy Product Changeover

No cleaning required—simply replace the tubing to switch products, making it ideal for small batch and multi-formula production lines.

4.Adjustable Filling Volume

The pump’s variable speed allows flexible adjustment for different bottles and volumes, ensuring consistent flow and stable output.

5.Compact and Durable Design

Built with 304 stainless steel, the machine is corrosion-resistant, space-saving, and easy to maintain, ensuring long-term performance.

6.Intelligent Operation Interface

Equipped with a touchscreen PLC interface, operators can easily set parameters such as volume, speed, and batch number for efficient control.

7.Versatile Application Range

Widely used in pharmaceutical, cosmetic, food, and beverage industries, this CE certified peristaltic pump liquid filling machine from China provides a reliable solution for particle-free, low-viscosity liquids.

Technical Parameters

| 1 | Voltage | 110/220V 50-60HZ 2KW |

| 2 | Filling pump | Peristaltic pump |

| 3 | Filling range | About 10-5000ml |

| 4 | Working capacity | 20-24BPM(based on 4 head) |

| 5 | Program control | PLC+Touch screen |

| 6 | Air | 0.6-0.8Mpa |