The Wet Glue Labeling Machine(Cold Glue Labeling Machine) is designed for high-speed, precise labeling of round bottles, jars, and cans across food, beverage, pharmaceutical, cosmetic, and chemical industries. It supports various bottle materials, including plastic, PET, glass, and metal, with adjustable parameters to handle different sizes and label formats.

Equipped with advanced sensors, the machine detects missing bottles or labels, preventing glue waste and ensuring accurate application. Its pneumatic glue feeding system combined with a pressing belt ensures uniform, bubble-free labeling, while the durable chain conveyor guarantees smooth bottle transport and low error rates.

Constructed from SUS304 stainless steel with high-quality imported components, it offers durability, easy maintenance, and long-term reliability. CE certification ensures compliance with EU safety standards, providing market access and consistent performance for global production lines.

Wet Glue Labeling Machine Main Feature

1.High-Precision Wet Glue Labeling for Round Containers

The Wet Glue Labeling Machine is designed for accurate and efficient labeling of round bottles made of glass, plastic, or metal. It is widely applied in the food, beverage, pharmaceutical, and chemical industries, offering stable and precise label application with a clean finish.

2.Durable and Hygienic Structure

Constructed entirely from 304 stainless steel and high-quality aluminum alloy, the machine meets GMP standards, ensuring durability, corrosion resistance, and easy maintenance for long-term industrial use.

3.Efficient Labeling and Gluing Mechanism

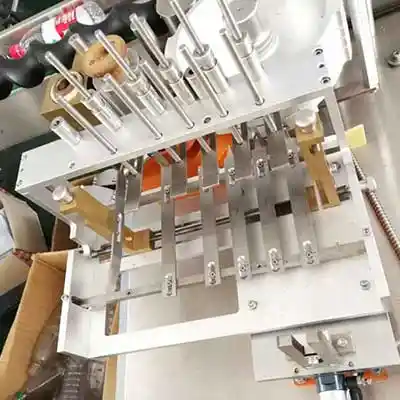

Equipped with an automatic label feeding and pasting system, the machine uses a high-purity copper glue box with a stainless-steel roller for precise and uniform glue application. The adjustable glue thickness minimizes waste and prevents glue leakage.

4.Smooth Bottle Handling and Accurate Positioning

The rotary-screw bottle guiding mechanism ensures stable bottle movement and precise positioning. Assisted by a vacuum suction system and conveyor belt coordination, labels are applied smoothly and securely without wrinkles or displacement.

5.Intelligent Control System for Easy Operation

Wet Glue Labeling Machine adopting a PLC control system and user-friendly touch screen interface, operators can easily adjust parameters, monitor production, and access online help. Automatic photoelectric tracking prevents mislabeling, no-label, or no-bottle operations, enhancing accuracy and reducing waste.

6.Flexible Operation and Quick Adjustment

The machine supports independent operation or integration with automated production lines. It features stepless speed regulation for labeling, conveying, and bottle separation, allowing users to easily adapt to different bottle sizes and production requirements without part replacement.

7.Easy Maintenance and Reliable Performance

Designed for practicality, the glue box, rubber roller, and rotary turret adopt a separated structure, enabling fast cleaning and maintenance. All electrical components are sourced from internationally recognized brands, ensuring stability, long lifespan, and minimal downtime.

Technical Parameters

| 1 | Labeling capacity(pcs/min) | 60-150 pcs/min (Related to the material and label size) |

| 2 | Labeling accuracy(mm) | ±1.0mm |

| 3 | Bottle size | Outside diameterφ30-φ100mm (H)20-150mm |

| 4 | Label size | (L)20-200mm(H)20-140mm |

| 5 | Air pressure | 5KG/cm2 |

| 5 | Power supply | AC220V 50Hz/60Hz 1800W |

Wet Glue Labeling Machine Workflow

The wet labeling process begins as bottles or tins are rolled into the machine, where a pressure belt gently guides them through the labeling pathway. As each container passes through the adhesive station, a precise application of resin glue coats the designated area. The label is then picked up by the applicator rod and smoothly transferred onto the container’s surface while it rotates, ensuring even and accurate placement. To secure the label, the end of the label receives an extra dab of adhesive, guaranteeing a firm bond throughout the container’s journey on the conveyor.

The wet glue labeling machine system is equipped with sensors that detect the presence of a container, ensuring labels are only dispensed when a bottle or tin is correctly positioned—eliminating unnecessary waste and maintaining high efficiency. The labeling speed can be easily adjusted, allowing flexible operation from low to high speeds depending on production requirements. Maintenance is straightforward, with accessible replacement parts and a simple tank change process designed to minimize downtime and maximize productivity.

How does the machine prevent bubbles and ensure a smooth label application?

Belt Pressing Mechanism for Bubble-Free Labeling

A dedicated belt pressing system applies consistent, firm pressure to each label immediately after application. This ensures every label adheres smoothly and tightly to the bottle surface, effectively eliminating bubbles or wrinkles. The result is a flawless finish that enhances both the precision of label placement and the overall visual appeal of your products.

How does the cans feeding delivery system and change tooling workin a labeling machine for different can sizes?

Various types of glue can be utilized with this machine. When switching containers, certain parts such as screws, belts, and sponges may need to be replaced. However, format changes are unnecessary for containers with similar diameters.

Flexible Container Handling

The machine features a dedicated feeding and delivery system, including a turntable for efficient can or bottle placement. When working with different container types or sizes, adjustments to the feeding components at the entry point may be required to ensure precise alignment and smooth operation. This flexibility allows for quick adaptation between production runs, making the machine suitable for a wide range of cylindrical bottles and cans across various industries.

What are the differences in print quality between wet-glue and self-adhesive labels?

Comparing Print Quality: Wet-Glue vs. Self-Adhesive Labels

When considering print quality, the gap between wet-glue (WG) and self-adhesive (SA) labels has virtually disappeared thanks to advances in printing technology. Traditionally, wet-glue labels have been produced using lithographic printing, delivering sharp, consistent results ideal for high-volume runs commonly found in food and beverage packaging.

However, self-adhesive labels have rapidly evolved. Originally limited to simpler applications such as basic price or barcode stickers, today’s SA labels are crafted with the latest combination presses, offering a wide range of graphic options and enhancements. These presses support not only litho printing but also a variety of other methods, enabling intricate designs, high-color fidelity, and special embellishments.

Leading industry experts now agree that both wet-glue and self-adhesive labels can achieve comparable levels of quality. Modern SA labels can match the precision and visual impact of litho-printed WG labels, and the choice between the two often hinges on additional factors like run length, cost efficiency, or specific container needs rather than pure print excellence.