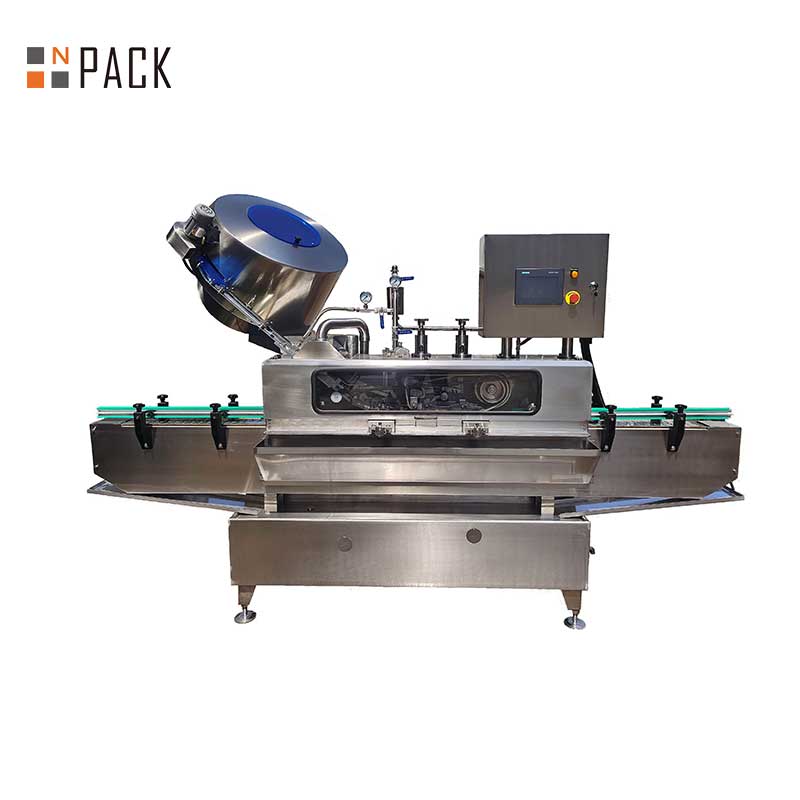

The Steam Vacuum Capping Machine is a high-efficiency solution for sealing glass jars and bottles with metal twist-off caps. It uses steam injection to remove air from the headspace before capping, forming a strong vacuum seal that enhances product freshness and shelf life.

Made of SUS304 stainless steel, the machine features PLC touch screen control, frequency conversion speed adjustment, and an automatic cap sorting system for stable, continuous operation. It supports three, four, or six-cap types and reaches speeds of up to 150 bottles per minute.

Widely used in the food, beverage, and condiment industries, this CE-certified machine ensures precise sealing, low noise, and high automation—ideal for modern vacuum packaging production lines.

Steam Vacuum Capping Machine Main Features

1.PLC Touch Screen Control Panel

Equipped with a PLC and touch screen interface, allowing easy monitoring, parameter adjustment, and intuitive operation for better control of the capping process.

2.Emergency Stop Button

Ensures safety by allowing immediate shutdown, protecting both operators and equipment in case of emergencies.

3.Electric Rotation Cover Sorting

Reduces noise and smoothens cap sorting for improved operational efficiency and a quieter working environment.

4.Automated Cap Feeding with Electric Eye

Metal twist-off caps are automatically detected and fed, reducing manual labor while increasing production speed and consistency.

5.Adjustable Guide Rail

Supports different cap sizes without extra parts, enhancing machine versatility and simplifying bottle or cap changes.

6.Steam Injection Pre-Sealing

Uses high-speed steam to displace air before sealing, improving vacuum formation in the bottle and extending product shelf life.

7.Two Flat Belts for Secure Sealing

Provides consistent and reliable cap tightening, ensuring stable and high-quality packaging results.

8.Integration with Steam Generator

Optional steam generator integration enhances sealing efficiency, making it ideal for products requiring vacuum-assisted preservation.

9.Versatile Bottle Compatibility

Handles round, square, and various other bottle shapes, offering flexibility across multiple packaging lines.

10.Seamless Production Line Integration

Can be connected with automatic filling and labeling machines for a fully automated production process.

Technical Parameters

| 1 | Model | NP-SVC |

| 2 | Production Capacity | 80–150 bottles/min (adjustable according to bottle and cap size) |

| 3 | Applicable Cap Type | Three-turn cap, four-turn cap, six-turn cap, and press-twist cap |

| 4 | Applicable Cap Diameter | Φ30–Φ90 mm |

| 5 | Applicable Bottle Diameter | Φ30–Φ100 mm |

| 6 | Applicable Bottle Height | 65–260 mm |

| 7 | Motor Power | 3.12 kW |

| 8 | Steam Consumption | 180–230 kg/h |

| 9 | Steam Pressure | ≤0.4 MPa |

| 10 | Max Pressure Inside Bottle | 67 kPa (502 mmHg) |

| 11 | Machine Weight | Approx. 1100 kg |

| 12 | Overall Dimensions | 3000 × 1100 × 2000 mm |

Stream Vacuum Capping Machine Main Advantages

1.Excellent Sealing Performance: Forms a vacuum seal that effectively prevents liquid leakage and protects the contents from oxidation and moisture.

2.Extended Shelf Life: Vacuum sealing inhibits bacterial growth, reduces the need for preservatives, and significantly prolongs product shelf life.

3.High Production Efficiency: High-speed automated design ensures fast and stable operation while reducing labor requirements.

4.Safety and Visual Assurance: The vacuum-induced concave center of the cap creates a “safety button,” providing a clear visual indication that the package is unopened.

Working Principle of Steam Vacuum Capping Machine

Steam vacuum capping machine operates based on thermal expansion and contraction. High-temperature steam is injected into the bottle to completely displace the internal cold air, after which the cap is immediately applied.

Steam Purging

Before capping, hot steam is blown into the bottle, heating both the container and the cap while effectively expelling the air inside.

Capping Operation

The cap is tightened while the steam and cap remain hot, ensuring proper closure under optimal conditions.

Vacuum Formation

As the steam cools, the internal gas contracts, creating negative pressure inside the bottle. This vacuum pulls the cap firmly into place, forming a secure and airtight seal.

This method is widely used for vacuum sealing condiments such as sauces, jams, and honey, helping maintain product quality and extend shelf life.