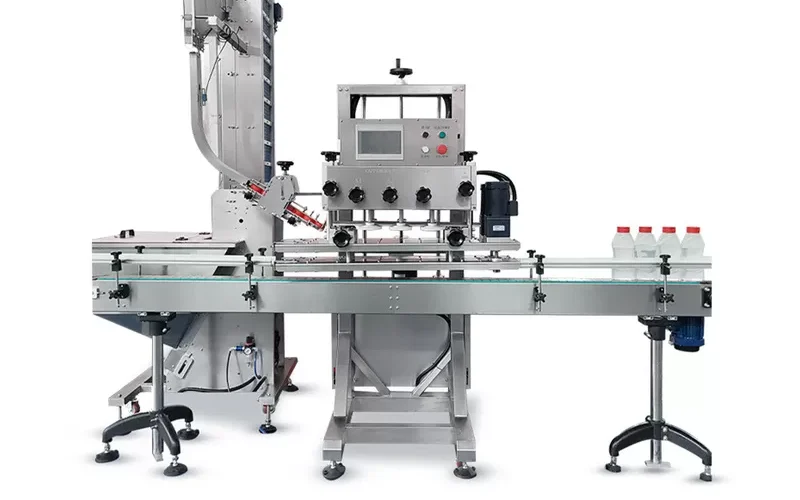

The Press Capping Machine is specially designed for press-on caps with plugs or stoppers, ensuring secure sealing to prevent leakage, contamination, and maintain product freshness. Built with durable SUS304 stainless steel, it guarantees hygiene, easy cleaning, and long service life.

Equipped with PLC and touch screen control, the machine offers adjustable capping speed, stable pneumatic or servo-driven operation, and wear-resistant pressing components to protect caps from damage. It supports bottles of different shapes and sizes, with a production capacity of 5000–7200 bottles per hour, achieving a capping yield of over 99%. The conveyor system ensures smooth and efficient bottle transfer, while the clamping and anti-dumping design keeps bottles stable during operation.

Certified with CE and RoHS standards, the Press Capping Machine meets international safety requirements and enables seamless integration into food, beverage, cosmetics, and pharmaceutical production lines.

Cap Pressing Mchine Main Features

1.Durable Stainless Steel Construction

Made from 304/316 stainless steel, the machine ensures corrosion resistance, hygiene, and long service life for demanding industrial environments.

2.Efficient PLC Control System

Equipped with a PLC and touch screen (English & Chinese), operators can easily monitor, adjust, and control the capping process, improving productivity and reducing human errors.

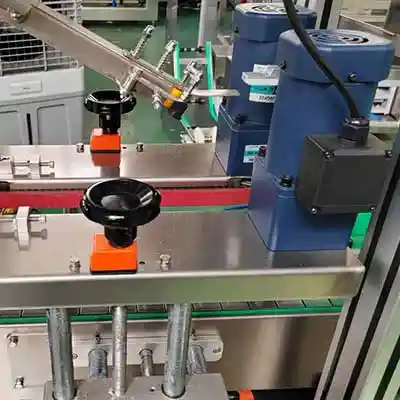

3.Flexible Bottle Clamping

The adjustable bottle clamping belt accommodates various bottle heights and shapes, ensuring precise alignment without replacing parts.

4.High-Speed and Stable Capping

press capping mechanism guarantees consistent performance with fast, precise sealing, enhancing production efficiency.

5.Seamless Integration with Production Lines

Can be combined with filling and labeling machines to create a fully automated packaging line, streamlining operations and reducing manual labor.

6.Easy Adjustment and Minimal Downtime

Quick adjustments to clamping and capping components allow rapid changeovers for different bottle types, saving time and lowering operational costs.

7.Reliable and User-Friendly Operation

Novel design with few faults ensures smooth operation; stepless variable frequency motor control allows adaptability to a wide range of bottle types and materials.

Technical Parameters

| 1 | Model | NP-PC |

| 2 | Applied bottle range | 100ml-1000ml 1000ml-5000ml |

| 3 | Applied cap size | Dia:12-120mm |

| 4 | Yield of capping | >99% |

| 5 | Power Supply | 220V 50HZ |

| 5 | Power Consumption | <2KW |

| 6 | Air Pressure | 0.4-0.6Mpa |

| 7 | Speed Control | Frequency Conversion |

| 8 | Single machine noise | <=70Db |

| 9 | Weight | 850kg |

| 10 | Dimension (LxWxH) | 2000x1100x1800(mm) |

| 11 | Production Capacity | 5000-7200 bottles/h |