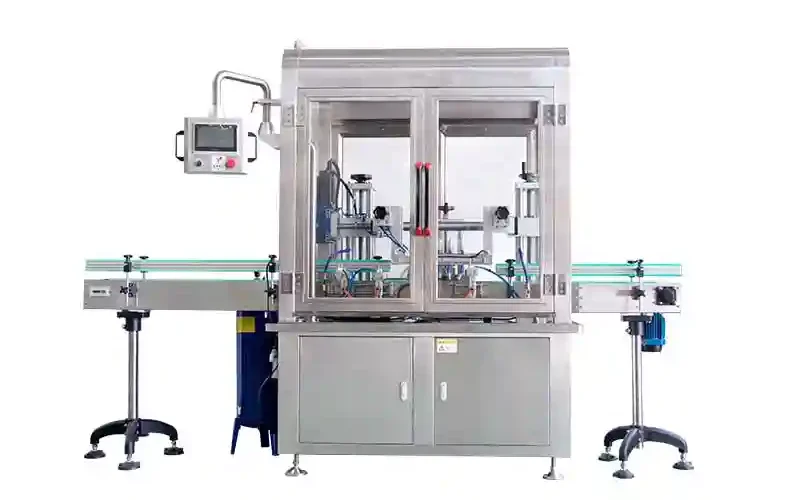

The Automatic Inverting Wet Bottle Rinsing Machine is designed for efficient internal cleaning of glass and plastic bottles before the filling process. Using high-pressure water, it effectively removes dust, debris, and contaminants left during bottle manufacturing, ensuring product purity and hygiene.

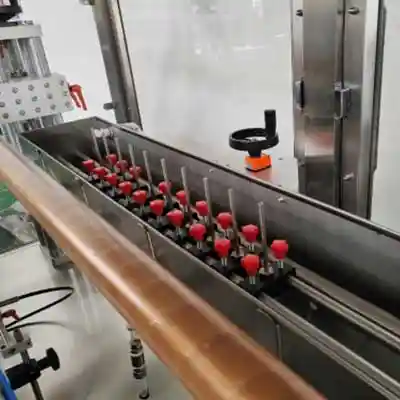

Equipped with 2 to 16 rinse heads, the machine inverts bottles for thorough rinsing, then automatically returns them to the conveyor for filling. The servo motor system guarantees smooth and precise bottle inversion, while soft gripping pads protect containers from damage.

Controlled by a PLC system with a touch screen interface, this rinser offers simple operation, adjustable parameters, and stable performance. Built from SUS304 stainless steel, it ensures durability, corrosion resistance, and easy maintenance. Compatible with filling, capping, and labeling machines, it provides a complete and reliable solution for automated bottle cleaning in food, beverage, cosmetic, and pharmaceutical production lines.

Automatic Wet Bottle Rinsing Machine Features

1.Optimized Bottle Sanitization

Uses high-pressure water and precise inverting mechanisms to remove dust, debris, and contaminants from bottles, ensuring hygienic preparation for filling.

2.Precision Bottle Positioning & Conveying

Servo-driven conveyors and adjustable belts maintain fixed distances, automatically orient bottles under rinsing nozzles, enhancing cleaning consistency and throughput.

3.Flexible Washing Programs

Customizable rinse cycles for different bottle shapes and sizes, with adjustable speed and programmable parameters for efficient handling of glass and plastic containers.

4.Advanced PLC Touchscreen Control

Intuitive interface enables real-time monitoring, quick adjustments, and automatic detection of bottle absence or misalignment to reduce downtime and maintain production efficiency.

5.Safety & Operator Protection

Transparent PVC safety covers, stainless steel doors, emergency stop buttons, and automatic error alarms ensure operator safety and maintain GMP-compliant cleaning conditions.

6.High Throughput & Productivity

Multi-head inverting rinsing combined with high-speed conveyors maximizes output, reduces processing time, and integrates seamlessly with automated liquid filling, capping, and labeling systems.

7.Durable & Sanitary Construction

304/316 stainless steel structure with reinforced gripping mechanisms, adjustable in-feed height, and lubricated transmission components provide long-term stability, hygiene, and low maintenance.

Technical Parameters

| 1 | Power | 220V 1Phase, 0.75KW |

| 2 | Applied Container | Plastic Bottles, Glass Bottles, Jars |

| 3 | Speed | 20-60b/m |

| 4 | Rinsing Heads | 4,6,8,10 12 and 16 heads |

| 5 | Air Pressure | 0.6MPA |

Wet Bottle Rinsing Machine Work

The inverting bottle rinsing machine lifts bottles from the conveyor and turns them upside down over a rinse basin. Each bottle is clamped securely and rinsed with water to remove dust and debris from the interior.

The machine operates automatically, rinsing multiple bottles at the same time with individual nozzles. After rinsing, debris drains into the basin, the bottles are returned to the upright position, released onto the conveyor, and sent directly to the filling machine. It is suitable for both glass and plastic bottles in various shapes and sizes.

Operation is controlled via a touchscreen with PLC control, allowing easy adjustment of rinse time and settings. Pre-set recipes enable fast changeover for different bottle sizes, ensuring clean containers and efficient, contamination-free production.

What Are Bottle Washing Machines Used For, and How Do They Differ from Rinsers?

Bottle rinsers are mainly used for quick internal cleaning just before filling, removing dust or light debris from new containers. Bottle washing machines, in contrast, are designed for thorough cleaning and sanitizing.

Key Differences:

Deeper cleaning: Bottle washers wash and sanitize bottles using multiple stages to remove residues and contaminants.

Inside and outside cleaning: They clean both the interior and exterior, unlike rinsers that focus only on the inside.

Wider application: Suitable for large or returnable bottles and customizable with pre-wash, wash, sanitizing, and rinse stages.

In short, rinsers are ideal for light, pre-filling cleaning, while bottle washing machines are the better choice for intensive washing and sanitizing, especially for reused or large containers.