Bleach (sodium hypochlorite solution) production involves a carefully controlled series of steps from raw material handling to final packaging. The typical concentration for household bleach ranges between 3-8% available chlorine, while industrial grades may contain 10-15%.Bleach (sodium hypochlorite solution) is a highly reactive chemical product used for disinfection, cleaning, and whitening. Below is a detailed overview of its full production, filling, and packaging process, including raw material handling, mixing, filling, packaging, and common packaging styles with capacities.

Sodium hydroxide (NaOH) solution (typically 25-30%) is prepared in a mixing tank

Chlorine gas (Cl₂) is carefully introduced under controlled conditions (temperature maintained at 30-40°C)

The reaction: Cl₂ + 2NaOH → NaClO + NaCl + H₂O

pH is maintained between 11-13 to ensure stability

The solution is continuously agitated for homogeneous mixingChlorine content testing via iodometric titration

pH monitoring with automatic sensors

Visual inspection for clarity and absence of particulates

The bleach solution passes through micron filters (5-10 microns) to remove any impurities

Sodium silicate may be added as a stabilizer (0.1-0.5% by weight)

Temperature is reduced to ambient (20-25°C) in cooling tanks

The solution rests for 24-48 hours for complete reaction and stabilization

Bottle Manufacturing: ◦ Material: High-Density Polyethylene (HDPE) is standard due to chemical resistance and durability. ◦ Design: ■ Child-Resistant Caps: Required for consumer safety. ■ Wide Mouth: Facilitates pouring and refilling. ■ Ribbed Grip: Improves handling. 2. Automated Filling: ◦ Filling Machines: ■ Gravity Fillers: For low-viscosity bleach (suitable for 1–5 L bottles). ■ Piston Fillers: High-precision volumetric filling for small bottles (250 mL–1 L). ■ Rotary Fillers: High-speed systems (10,000+ bottles/hour) with mass flow meters. ◦ Nitrogen Purging: Inert gas displaces oxygen in bottles to prevent NaClO degradation. ◦ Leak Testing: Pressure decay or vacuum tests to ensure seal integrity.

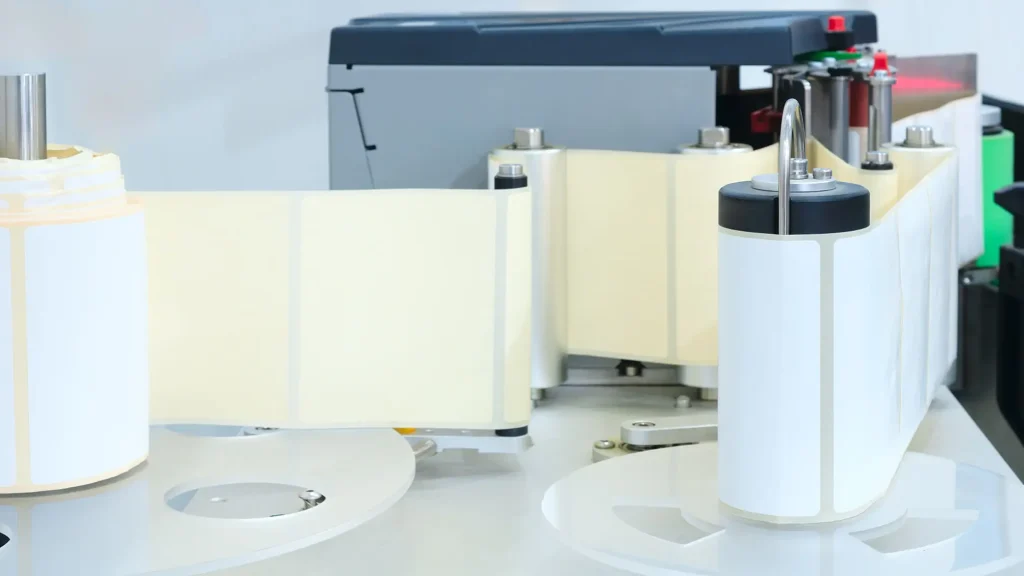

Capping: Torque-controlled cappers apply consistent force to prevent leaks. ◦ Labeling: ■ Material: Water-resistant synthetic labels with safety warnings (e.g., “Corrosive,” “Do Not Mix with Ammonia”). ■ Printing: UV-resistant ink for batch numbers, expiry dates, and regulatory symbols (e.g., GHS hazard pictograms).

Cartoning: Bottles packed into corrugated boxes (e.g., 6 or 12 units/box). ◦ Shrink Wrapping: Bundled bottles for bulk retail display. ◦ Palletizing: Automated robots stack boxes onto pallets (e.g., 1,000–2,000 bottles/pallet).

Ventilation Systems: Acid-resistant exhausts to manage chlorine fumes. ◦ Spill Containment: Drip trays and emergency shutoff valves.